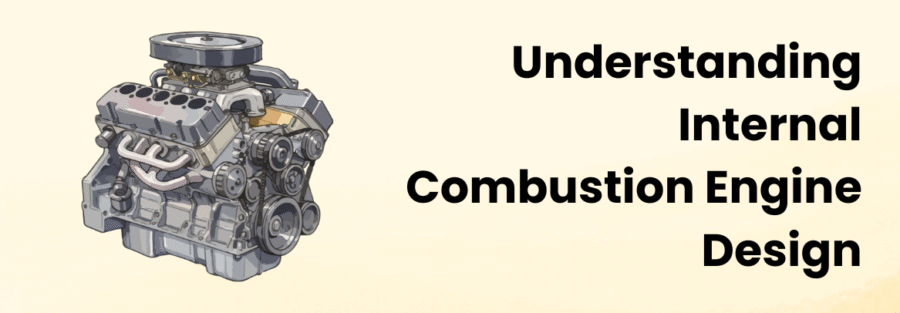

The internal combustion engine (ICE) remains one of the most complex and finely balanced systems in modern engineering. Even as the industry evolves toward electrification, the principles of ICE design continue to be essential — from hybrid powertrains to high-efficiency engines used in performance, industrial, and commercial applications.

At Caliber Technologies LLC, we specialize in advanced simulation-driven engine design and optimization, helping OEMs and Tier-1 suppliers develop engines that meet demanding targets for strength, durability, NVH, fuel efficiency, and thermal performance. Our multidisciplinary team leverages CAE, MBD, FEA, and CFD to predict, refine, and validate critical performance aspects early in the design cycle — reducing the need for physical prototypes and accelerating time-to-market.

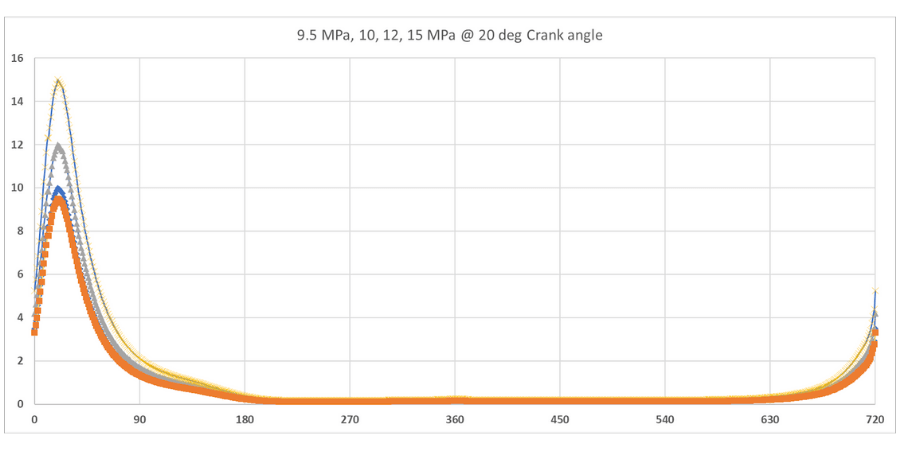

1) Thermal Analysis for Predicting Peak Cylinder Pressure

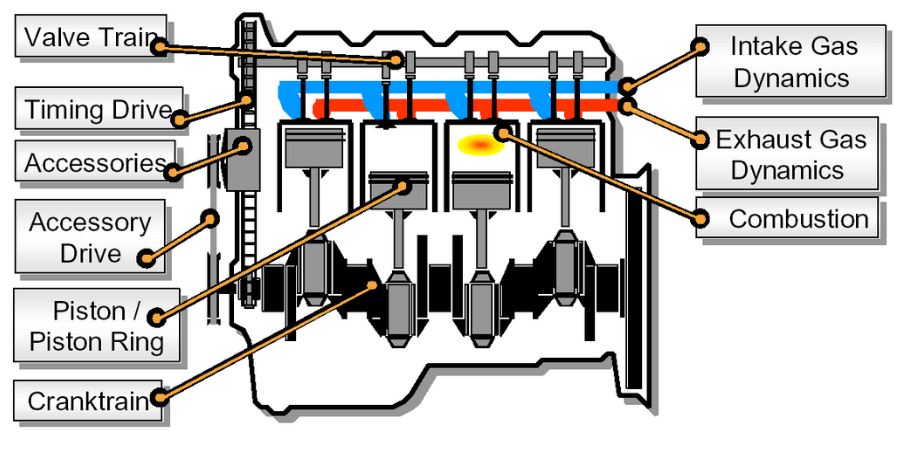

Understanding and predicting peak cylinder pressure is crucial to defining the overall loading environment of an engine. Caliber Technologies uses advanced thermal and combustion analysis techniques to evaluate temperature gradients, heat transfer rates, and thermal stresses across combustion chambers, piston crowns, and cylinder heads.

This allows our engineers to accurately predict pressure rise rates and combustion-induced thermal loading, helping our clients design components that withstand extreme conditions while maintaining efficiency and emissions compliance.

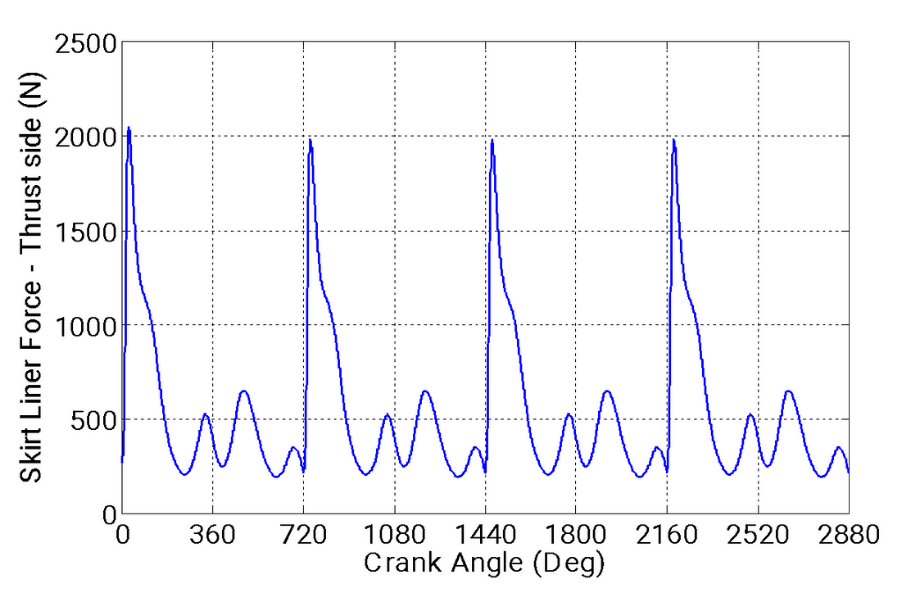

2) Multibody Dynamics (MBD) Simulation for Power Cylinder Loading

The piston, connecting rod, and crankshaft system form the mechanical heart of an ICE. Caliber Technologies performs Multibody Dynamics (MBD) simulations using industry-leading tools to estimate realistic loading on the piston assembly, connecting rod, journal bearings, and crankshaft.

By simulating the complete kinematic and dynamic behavior of the crank-train system, we help clients quantify inertia forces, side thrusts, and bearing loads under various operating conditions. This enables accurate input loads for subsequent structural and fatigue analysis, resulting in lighter, stronger, and more reliable designs.

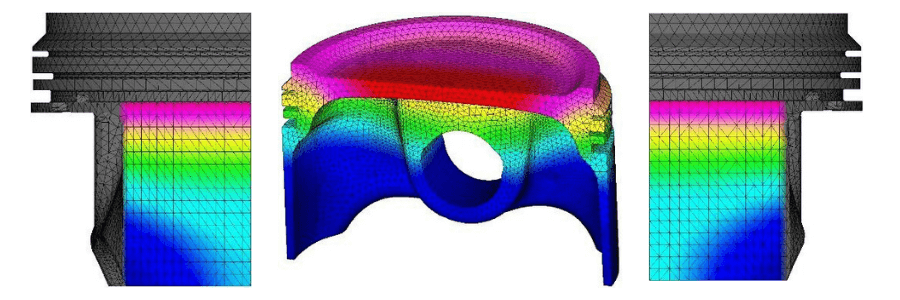

3) Structural Analysis for Strength, Durability, and Fatigue

Once the dynamic loading environment is defined, our experts employ Finite Element Analysis (FEA) to assess structural strength, durability, and fatigue life of critical components such as the piston, connecting rod, crankshaft, and cylinder block.

Using advanced nonlinear material models, contact definitions, and fatigue prediction tools, Caliber Technologies ensures every design meets target life cycles and safety margins. These insights empower OEMs to refine geometry, reduce mass, and enhance performance while maintaining structural integrity across the full duty cycle.

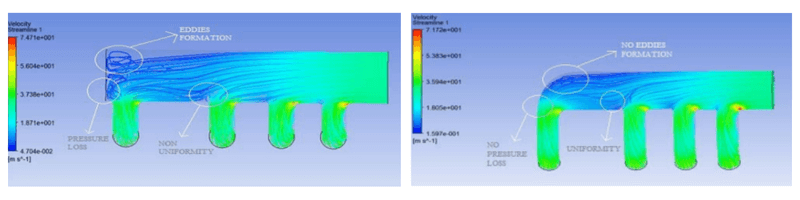

4) Cooling Duct Sizing and CFD-Based Thermal Optimization

Efficient thermal management is essential to maintaining optimal operating temperatures and preventing localized overheating. Caliber Technologies applies Computational Fluid Dynamics (CFD) to evaluate coolant flow, pressure drop, and heat transfer through the engine’s cooling ducts and passages.

Our engineers perform cooling duct sizing and flow-rate optimization, ensuring uniform temperature distribution and improved thermal efficiency. This leads to better durability, reduced friction losses, and improved fuel economy — key aspects of next-generation engine designs.

Caliber Technologies: Research-Driven Engine Design Excellence

Caliber Technologies has published state-of-the-art research papers in advanced engine design optimization, focusing on the integration of MBD, FEA, and CFD-based approaches for power cylinder and thermal system performance.

Our multidisciplinary expertise helps clients address key performance objectives such as:

- Structural strength and fatigue durability

- Thermal and cooling efficiency

- NVH refinement

- Fuel economy and emission optimization

By combining simulation expertise, domain knowledge, and real-world validation, Caliber Technologies empowers engineering teams to develop more efficient, durable, and competitive internal combustion engines.

Example: Intake manifold redesign using CFD

Partner with Caliber Technologies

From concept to validation, Caliber Technologies serves as an extension of your engineering team, bringing deep domain expertise and advanced virtual validation capabilities to every project.

Let’s collaborate to design your next high-performance, efficient, and durable engine system. E-mail us at operations@thecalibertech.com.