Background and Introduction

Slide-out systems in Recreational Vehicles (RVs) offer essential benefits for both functionality and comfort. These systems allow the living space of the RV to expand when parked, providing increased interior space without increasing the vehicle’s overall length while driving. However, the slide-out structure—comprising both the frame and wall panel—presents unique engineering challenges, primarily due to the dynamic loading conditions, potential for misalignment, and the risk of sagging, which can lead to serious issues such as water leakage and structural failure over time.

The slide-out must be designed to handle a wide range of forces, including vertical loads, lateral forces, and torsional moments, all while maintaining alignment with the main structure of the RV. Misfit, deformation, and sag in the frame can compromise the integrity of the structure, leading to problems such as water leaks between the slide-out and the main RV wall. These issues not only affect the performance and longevity of the RV but also result in poor customer experiences and can significantly damage the brand reputation of manufacturers.

Addressing these challenges requires more than just basic structural design. Traditional engineering methods, including static calculations and simple material choices, often fall short in identifying the root causes of structural misalignment, deflection, and fatigue that lead to these problems. To ensure the long-term durability and reliability of the slide-out system, Caliber Technologies employs advanced digital engineering techniques, such as Finite Element Analysis (FEA), normal mode analysis, and multi-load case simulations to create a robust and highly accurate design that accounts for real-world conditions.

This article discusses the role of Caliber Technologies in addressing the structural challenges of RV slide-out designs, focusing on the key aspects of frame integrity, wall attachment, load distribution, and the importance of digital engineering techniques in ensuring a high-quality, long-lasting slide-out system.

The Structural Challenges of RV Slide-Outs

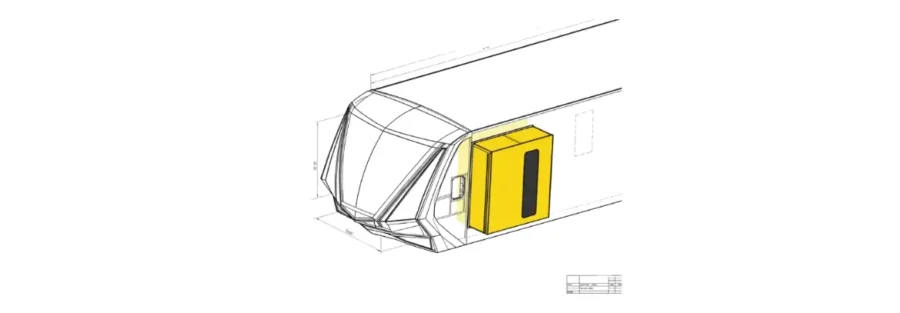

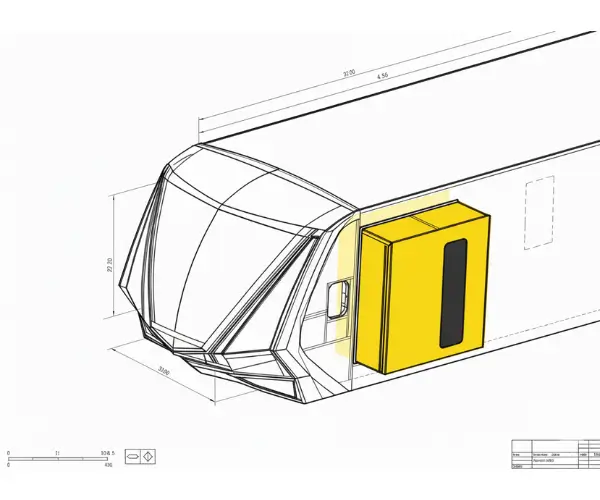

RV slide-out systems consist of two primary components: the frame structure and the wall panel. The frame is the load-bearing element, typically constructed from lightweight yet durable materials, and supports the mechanism that extends and retracts the slide-out. The wall panel, which is part of the superstructure of the RV, must also be securely attached to the frame and must maintain its integrity as the slide-out extends and retracts.

The frame of the slide-out is subjected to complex forces when extended. These forces include vertical loads, torsional moments, and shear forces, which can cause the frame to sag or misalign. Over time, if the frame is not designed to withstand these forces, misalignment can occur, resulting in the slide-out shifting or becoming misaligned with the RV’s main structure. This misalignment can create gaps between the slide-out and the main body of the RV, leading to potential water intrusion, air leakage, and energy inefficiency.

The wall panel attached to the frame also plays a significant role in maintaining the structural integrity of the slide-out. If the panel is not adequately supported, it may experience deflection or warping under load, which exacerbates alignment issues. The attachment of the wall panel to the frame must be carefully engineered to prevent these issues while ensuring the system can handle the dynamic forces from the RV’s suspension and road conditions.

One of the most common issues that arise from slide-out misalignment is water leakage. When the frame sags or becomes misaligned, the gap between the slide-out and the RV wall widens, creating pathways for water to enter, especially during rainfall or when washing the RV. Over time, moisture intrusion can cause damage to the RV’s interior, including wood rot, mold growth, and structural deterioration. The presence of water can also compromise electrical systems, insulation, and interior finishes, further impacting the durability and safety of the RV.

Additionally, sagging of the slide-out frame can lead to poor load distribution along the floor and frame of the RV. This uneven load distribution can cause stress concentrations and further exacerbate deflection, leading to long-term structural degradation.

Digital Engineering Approach by Caliber Technologies

At Caliber Technologies, we go beyond traditional structural analysis methods to ensure that the slide-out system is engineered for optimal performance and durability. We employ a digital engineering approach using advanced Finite Element Analysis (FEA), normal mode analysis, and multi-load case simulations to analyze and redesign the structure for better alignment, load distribution, and vibration management.

Multi-Load Case Analysis

The slide-out structure is exposed to a wide range of load cases during operation. These include the static load of the slide-out when parked, the dynamic loads when driving, and the forces encountered from wind, road imperfections, and suspension dynamics. Traditional engineering techniques often rely on simplified loading conditions, which fail to capture the complexity of real-world environments.

Caliber Technologies creates multiple load case scenarios to simulate a variety of real-world conditions:

- Parked RV load cases: Simulating the forces acting on the slide-out when the RV is stationary, including the weight of the slide-out and any additional loads, such as cargo or furnishings inside.

- Tilted RV conditions: Since RVs are rarely parked on completely flat ground, we simulate the effects of different RV angles to ensure the slide-out can maintain its integrity under skewed loads.

- Dynamic loads: These simulate the forces acting on the slide-out when the RV is in motion, including those resulting from acceleration, braking, suspension movements, and road vibrations.

FEA for Frame and Wall Panel Optimization

Through FEA, we create detailed 3D models of the entire slide-out system, including the frame structure and wall panels, to identify weak points and optimize the design. The FEA model allows us to simulate how the frame and wall panel react to a variety of forces, including: Bending and torsional moments applied by the slide-out mechanism, compression and shear forces that result from load distribution and vehicle movement

This approach enables us to assess the deformation and stress distribution across the entire slide-out assembly, ensuring that critical areas are reinforced and that materials are used efficiently without unnecessary over-engineering.

Normal Mode and Vibration Analysis

Beyond static load cases, vibration is a critical aspect of slide-out design. The constant motion of the RV, coupled with road irregularities and driving conditions, introduces vibrational forces that can lead to fatigue and misalignment of the slide-out over time. Normal mode analysis is used to evaluate the natural frequencies and vibrational modes of the slide-out frame, identifying any potential resonance issues that could lead to accelerated wear or structural failure.

Through this analysis, Caliber Technologies engineers can adjust the design of the frame and wall attachment points to improve damping and resonance management, ensuring that the slide-out operates smoothly and without unnecessary vibrations.

How This Approach Helps

The use of advanced digital engineering techniques provides significant advantages in designing a robust and reliable slide-out system for RVs. By simulating real-world conditions and refining the design based on the insights gained from FEA and vibration analysis, we can address the most common structural challenges associated with slide-outs.

- Robust Structural Design: Through comprehensive load case analysis and FEA simulations, Caliber Technologies ensures that the slide-out frame is optimally reinforced to handle the complex forces acting upon it. This robust design minimizes the risk of misalignment, sagging, and water leaks, which are the primary sources of customer complaints in RV slide-out systems.

- Improved Load Distribution: Our digital engineering approach helps ensure that load distribution along the frame and floor is even, reducing the likelihood of stress concentrations and premature wear. This also improves the overall structural integrity of the RV and prolongs its service life.

- Enhanced Customer Satisfaction: By preventing common issues like misalignment, sag, and water intrusion, manufacturers can deliver a more reliable and durable slide-out system, leading to increased customer satisfaction. This, in turn, strengthens brand reputation and reduces costly warranty claims.

Conclusion

The structural design of slide-out systems in RVs is a critical factor in ensuring long-term durability, performance, and customer satisfaction. Caliber Technologies’ advanced digital engineering approach, which includes FEA, normal mode analysis, and multi-load case simulations, enables RV manufacturers to address the complex structural challenges associated with slide-out frames and wall panels.

By simulating real-world conditions and optimizing the frame and wall attachment points, Caliber Technologies delivers designs that are stronger, more reliable, and better able to withstand the dynamic forces encountered during RV use. This results in reduced risk of misalignment, sagging, and water leakage, ultimately leading to better customer experiences and improved brand reputation.

In an industry where quality and reliability are paramount, Caliber Technologies helps RV manufacturers build better products, faster and more efficiently, using the latest in digital engineering techniques. For more information on how Caliber Technologies can help with RV slide-out design and structural