Introduction and Background

The structural integrity and long-term durability of a recreational vehicle (RV) are influenced by a wide array of factors, but one of the most critical—and often underestimated—elements is the suspension system. Whether it’s a single-axle or multi-axle trailer, the suspension serves as the primary interface between the RV and the road. It plays a crucial role in absorbing road-induced loads, minimizing vibrations, and reducing the stress transmitted to the frame, body, and interior components.

In real-world operation, RVs experience a highly dynamic environment. Unlike passenger vehicles, which operate primarily on paved roads with well-controlled suspension systems, RVs are frequently exposed to uneven terrains, varying load distributions, and a wide range of operating conditions. Over time, these repeated load inputs can lead to a series of structural issues that compromise both performance and longevity. Common failure modes observed across the RV industry include:

- Cracked frames and cross members, often caused by localized stress concentrations and fatigue under cyclic loading.

- Wall and roof separation, resulting from excessive torsional flexing of the main frame.

- Floor delamination and cracking, due to poor load distribution and shock transfer from the suspension.

- Interior panel cracking, caused by high-frequency vibrations and misalignment between the chassis and body mounts.

The root cause of many of these failures is not simply poor material selection or inadequate weld design, but rather excessive road-induced loading transmitted through the suspension into the RV’s structural system. When the suspension is not properly matched to the vehicle’s mass, geometry, and stiffness characteristics, it can amplify road inputs rather than isolate them.

Minimizing these loads is therefore one of the most effective ways to mitigate long-term fatigue and reduce warranty issues associated with structural degradation. A well-designed suspension system can significantly enhance ride comfort, durability, and NVH (Noise, Vibration, and Harshness) performance—directly translating into better customer satisfaction and brand reputation.

However, the RV industry has historically been highly dependent on its suppliers for suspension system selection and tuning. While suppliers bring extensive component expertise, this dependency often limits RV OEMs’ ability to align suspension performance with the specific architecture, mass distribution, and target performance attributes of their unique RV designs. In most cases, RV OEMs adopt “off-the-shelf” suspension solutions that meet baseline specifications but fall short of delivering optimized vehicle-level performance.

To overcome these limitations, RV OEMs must take a systems engineering approach—defining high-level suspension requirements based on their product architecture, target market, and performance goals, then working collaboratively with suppliers to implement the right system. This is where Caliber Technologies provides a decisive advantage.

Caliber Technologies’ Capabilities in RV Suspension Design

Caliber Technologies (www.thecalibertech.com) offers a comprehensive engineering solution to help RV manufacturers select, design, and validate the most effective suspension system for their vehicles. Our team combines deep expertise in vehicle dynamics, Finite Element Analysis (FEA), and Multi-Body Dynamics (MBD) to deliver optimized suspension designs that improve durability, safety, and comfort.

We have advised several RV manufacturers and their suppliers in the evaluation and integration of various suspension configurations, including:

- Leaf Spring Suspension Systems

- Coil Spring Suspension Systems

- Air Suspension Systems

- Torsion Bar and Rubber Torsion Axle Systems

Each system offers unique advantages and trade-offs depending on vehicle mass, intended usage, ride targets, and cost structure. Caliber Technologies assists manufacturers in defining these trade-offs early in the product development cycle to ensure optimal system performance.

Suspension System Types and Selection Criteria

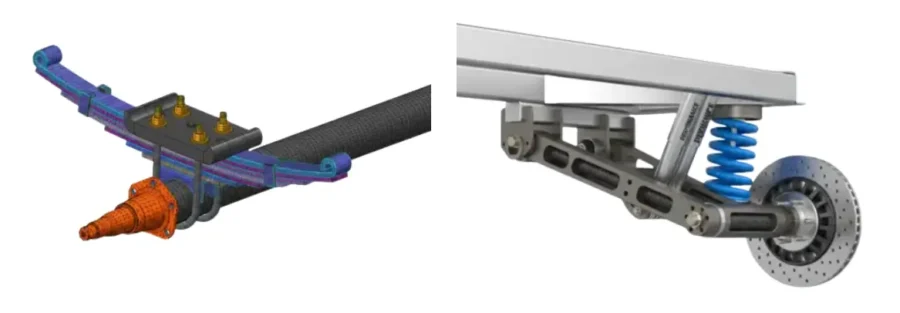

Leaf Spring Suspension

Leaf spring suspensions remain the most common choice in the RV industry due to their simplicity, cost-effectiveness, and load-carrying capacity. However, traditional leaf spring designs tend to have limited damping capabilities and can transfer high levels of vibration into the frame.

Caliber Technologies uses FEA to model stress distribution in leaf spring assemblies and mounts, optimizing geometry, pre-load, and material characteristics to reduce failure risks. Our MBD simulations evaluate axle articulation, bump and rebound travel, and load transfer, allowing us to refine shackle angles, bushing compliance, and bracket stiffness for better ride isolation.

Coil Spring Suspension

Coil spring systems offer improved ride comfort and wheel control compared to leaf springs, particularly for lighter or mid-weight trailers. The linearity of the spring rate allows for more predictable behavior and greater tuning flexibility.

Caliber Technologies helps OEMs determine whether coil spring systems are suitable for their trailer architecture by performing frequency response and load path simulations. Using multi-body dynamic models, we identify optimal spring rates and damping coefficients that balance comfort with handling stability. Structural FEA is then applied to validate mounting brackets and attachment points to prevent fatigue failures in the supporting frame.

Air Suspension Systems

Air suspension systems represent the highest tier of ride performance and load adaptability. By varying air pressure in the air springs, these systems can maintain consistent ride height across different load conditions and offer superior vibration isolation.

Caliber Technologies employs co-simulation techniques—integrating CFD-based air spring behavior with MBD models—to predict performance under varying road and environmental conditions. We also use FEA to design and validate air bag brackets, control arms, and linkages for structural robustness. Our engineering expertise ensures that air suspension integration does not compromise frame stiffness, ground clearance, or weight balance.

Multi-Axle Systems

For tandem or tri-axle trailer configurations, inter-axle load sharing becomes critical. Poor suspension equalization can lead to uneven load distribution, premature tire wear, and localized frame fatigue.

Caliber Technologies’ MBD simulations model axle-to-axle load transfer across different suspension geometries and stiffness ratios. Through parametric sweeps, we determine the ideal balance between equalization link stiffness, shackle geometry, and spring rates, ensuring smooth and consistent load sharing under various road profiles.

Advanced Analysis and Simulation Techniques

Caliber Technologies deploys state-of-the-art digital engineering tools to evaluate and optimize RV suspension systems at both the component and vehicle levels.

Finite Element Analysis (FEA)

FEA allows us to simulate the structural performance of suspension components and their integration into the RV chassis. By applying road-induced loads and boundary conditions, we can assess:

- Stress and strain distributions in brackets, arms, and bushings

- Fatigue life prediction for critical joints and welds

- Impact of suspension loads on the RV frame and superstructure

These analyses enable the identification of high-stress areas and guide design modifications to ensure components last the full life of the vehicle.

Multi-Body Dynamics (MBD)

MBD modeling is essential for capturing the dynamic behavior of the suspension system and its interaction with the vehicle structure. Caliber Technologies uses MBD simulations to study:

- Vertical and lateral load transfer under various road conditions

- Dynamic wheel loads and their influence on tire contact patch stability

- Pitch and roll behavior during acceleration, braking, and cornering

- Ride frequency tuning to align with optimal comfort zones for RV occupants

By correlating these simulations with real-world proving ground data, we can refine damping and stiffness parameters to achieve desired ride and handling performance.

Coupled Frame and Suspension Analysis

Caliber Technologies integrates suspension models directly with the RV frame and body structures to study load transmission paths and their effect on overall vehicle fatigue. This coupled approach allows us to quantify how suspension design decisions affect frame deflection, joint stress, and wall crack propagation—closing the loop between component design and full-vehicle durability.

Driving OEM-Led Suspension Architecture Development

While suppliers provide critical component expertise, Caliber Technologies believes that OEMs should drive high-level suspension architecture definition based on their unique product goals and vehicle characteristics. Our role is to empower OEMs with data-driven engineering insights that allow them to:

- Define performance targets (ride quality, durability, load handling).

- Select the most appropriate suspension architecture.

- Collaborate with suppliers to tailor designs that meet OEM-specific requirements.

This strategic approach enables RV manufacturers to differentiate their products not just by interior design and features, but by superior structural performance, ride quality, and long-term reliability.

Conclusion

As the RV market continues to evolve—with customers demanding more comfort, longer durability, and better performance—suspension optimization will remain a critical differentiator for RV OEMs.

Caliber Technologies brings decades of automotive-grade simulation and design experience to the RV industry, offering a complete suite of tools and expertise to help manufacturers select and validate the right suspension architecture. From leaf spring systems to air suspensions, from single-axle trailers to multi-axle platforms, our digital engineering approach ensures that each component is optimized for strength, durability, and ride performance.

By minimizing road-induced loads transmitted into the RV frame, Caliber Technologies helps OEMs eliminate the root causes of structural failures—enhancing reliability, improving customer satisfaction, and positioning their products as leaders in engineering excellence.