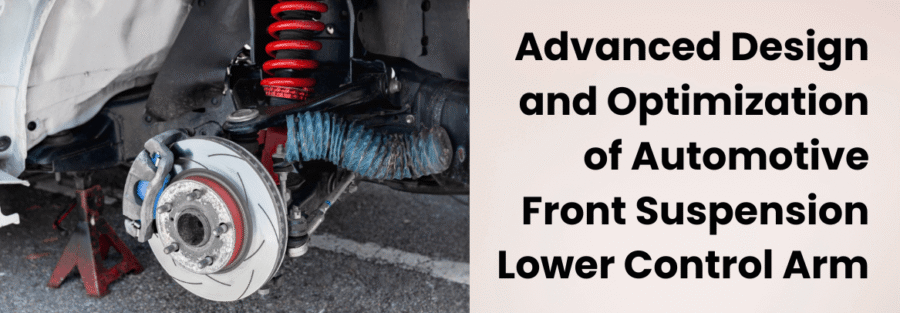

In modern vehicle engineering, suspension systems play a pivotal role in determining ride comfort, handling performance, and vehicle safety. Among the critical components of a suspension assembly, the front lower control arm (LCA) serves as a primary structural link that connects the chassis to the wheel assembly, enabling controlled motion and precise wheel alignment under dynamic driving conditions.

At Caliber Technologies LLC, we specialize in the design, simulation, and optimization of suspension components using advanced multi-body dynamics (MBD) and finite element analysis (FEA) techniques. Our integrated approach combines vehicle-level dynamics analysis in ADAMS/Car with component-level structural optimization, ensuring that every design meets performance, durability, and weight reduction goals.

Cascading Vehicle-Level Loads to Component-Level Design

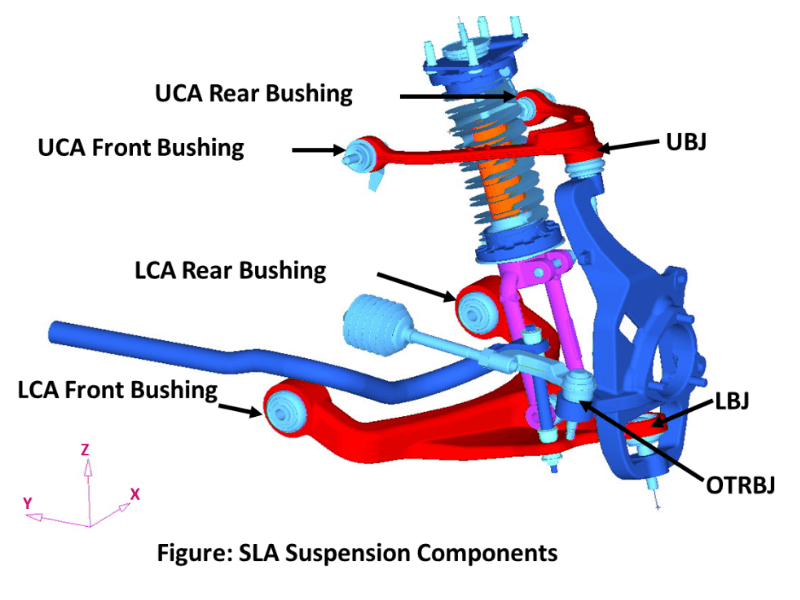

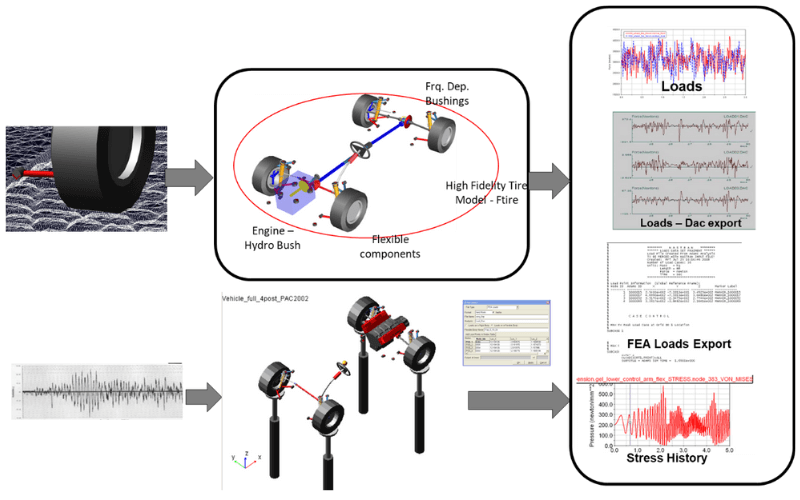

A critical challenge in suspension design is accurately translating vehicle-level operating conditions into realistic component-level loads. To achieve this, Caliber Technologies employs ADAMS/Car, a powerful multi-body dynamics simulation platform that enables full-vehicle modeling and analysis.

Our engineers develop a detailed full-vehicle MBD model that includes suspension kinematics, tire models, chassis connections, and powertrain effects. The model is subjected to a wide range of maneuvers—such as braking, cornering, bump, and ride events—to capture realistic dynamic load cases.

These simulations yield force and moment data at the suspension joints and bushings, which are then cascaded down to the component level. Specifically, the front suspension lower control arm experiences combined vertical, longitudinal, and lateral loads that vary depending on driving conditions and vehicle setup.

By extracting and processing these load-time histories from ADAMS/Car, Caliber Technologies generates a comprehensive load spectrum for subsequent FEA-based structural assessment. This methodology bridges the gap between system-level vehicle dynamics and component-level stress analysis—delivering true physics-based validation.

FEA-Based Structural Simulation and Optimization

Once the MBD-derived loads are established, our team performs detailed static, dynamic, and peak load structural FEA to evaluate and optimize the lower control arm design.

- Static Load Analysis: Static FEA simulations are performed to assess overall stiffness, stress distribution, and deformation under representative load cases. This ensures that the LCA maintains geometric stability and alignment integrity throughout its operating range.

- Dynamic Load Analysis: Using the transient load data from ADAMS/Car, a dynamic structural simulation is carried out to understand time-varying stress and strain behavior. This step is critical for predicting fatigue hotspots and assessing durability under realistic road conditions.

- Peak Load Case Analysis: Extreme load cases—such as pothole impacts or curb strikes—are analyzed to ensure the structure withstands rare but critical events without yielding or failure.

- Optimization and Weight Reduction: The insights gained from these analyses guide an iterative design optimization process focused on weight reduction, stiffness improvement, and fatigue resistance. Through careful geometry refinement and material selection, Caliber Technologies successfully achieved a 10% reduction in LCA weight while maintaining structural integrity and safety margins.

Kinematics and Compliance (K&C) Optimization

Structural performance alone is not enough; suspension geometry and compliance characteristics directly influence vehicle handling and steering response.

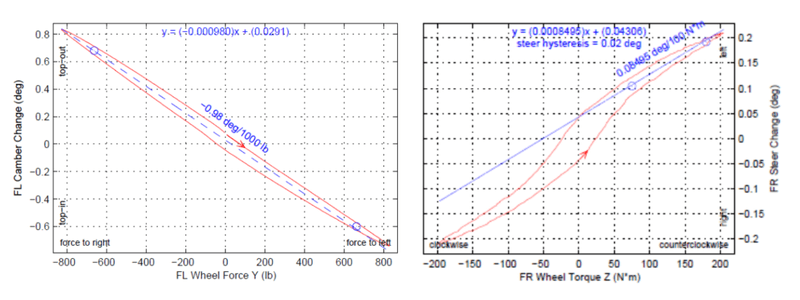

Caliber Technologies engineers conduct detailed Kinematics and Compliance (K&C) analysis to optimize the hard points and bushing characteristics of the front suspension system. Using ADAMS/Car, multiple configurations of lower control arm bushings and hard point locations are evaluated to study their impact on toe, camber, caster, and roll steer behavior.

This parametric study allowed for fine-tuning of understeer characteristics by strategically modifying hard point positions and bushing stiffness properties. The result was a suspension design with improved handling balance—achieving higher understeer for enhanced vehicle stability—while maintaining ride comfort and component durability.

Integrated MBD–FEA Workflow Benefits

By integrating multi-body dynamics and finite element analysis, Caliber Technologies delivers a data-driven, simulation-based suspension design process that provides measurable advantages:

- Accurate Load Transfer: Realistic, vehicle-level load inputs for structural FEA validation.

- Optimized Structural Performance: Enhanced stiffness-to-weight ratio with a 10% reduction in mass.

- Improved Handling: Refined understeer characteristics through bushing and hard point optimization.

- Enhanced Durability: Fatigue-resistant structure validated under real-world dynamic loading.

- Reduced Prototyping Cost: Virtual validation minimizes the need for expensive physical tests.

Conclusion

The front suspension lower control arm exemplifies the synergy between vehicle dynamics, structural analysis, and optimization. By integrating ADAMS/Car-based load extraction with FEA-based design validation, Caliber Technologies enables OEMs and Tier-1 suppliers to develop lightweight, durable, and dynamically optimized suspension systems that meet stringent performance and safety requirements.

Our multi-disciplinary approach—combining MBD, FEA, and K&C analysis—not only enhances vehicle ride and handling but also contributes to significant weight and cost savings, paving the way for next-generation suspension designs.