Background and Introduction

Recreational Vehicles (RVs), especially 5th wheel towables, present unique engineering challenges due to their complex structural requirements and the diverse range of loading conditions they encounter. Unlike conventional travel trailers with uniform frame heights, fifth wheels incorporate a distinctive elevated front section—the upper deck or “gooseneck”—that extends over the tow vehicle’s bed. This architectural feature, while providing spacious interior layouts and desirable features such as master bedrooms with increased headroom, introduces profound structural engineering challenges that demand sophisticated analysis and design optimization.

The upper deck structure creates a cantilevered or semi-cantilevered load condition where significant mass is supported at an elevated position, generating substantial bending moments that propagate through the frame system. This elevated section must maintain structural integrity while supporting bedroom furniture, slideout mechanisms, storage compartments, and occupant loads—all while the vehicle experiences dynamic loading from highway travel, articulation at the kingpin connection, and torsional inputs from uneven terrain.

Unlike traditional RV frames, the upper deck portion is particularly vulnerable to higher levels of stress, deformation, and fatigue, especially when subjected to the dynamic loads encountered during towing. Because of the height and the resulting moments applied to the frame, the upper deck is more likely to suffer from low-cycle fatigue, excessive deflection, and vibration-related issues. These structural issues can lead to reduced performance, compromised safety, and, ultimately, shorter service life of the RV.

Traditional engineering approaches, including basic calculations, are often insufficient for addressing the complex load scenarios and dynamic behavior of the upper deck frame. Given the wide range of real-world conditions—such as uneven terrain, varying road conditions, and unpredictable weight distribution—a more sophisticated analysis method is required. Digital Engineering with use of Finite Element Analysis (FEA) is a key to ensure that the upper deck frame of 5th wheel towable RVs can withstand these rigorous demands while maintaining safety, ride comfort, and longevity.

This article discusses the digital engineering approach pioneered by Caliber Technologies, which goes beyond basic beam theory calculations to ensure that the upper deck frame of 5th wheel RVs meets stringent performance and durability requirements.

Digital Engineering Approach by Caliber Technologies

Caliber Technologies employs an advanced digital engineering approach that combines Finite Element Analysis (FEA) with nonlinear static analysis, normal mode analysis, and transfer path assessment principles to optimize the design of the upper deck frame in 5th wheel towable RVs. This approach ensures that the frame design is capable of handling the complex loading environments encountered during towing, including both static and dynamic forces.

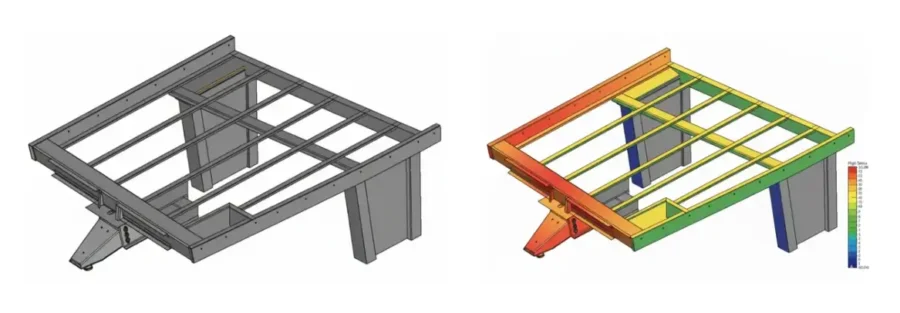

FEA-Based Structural Analysis

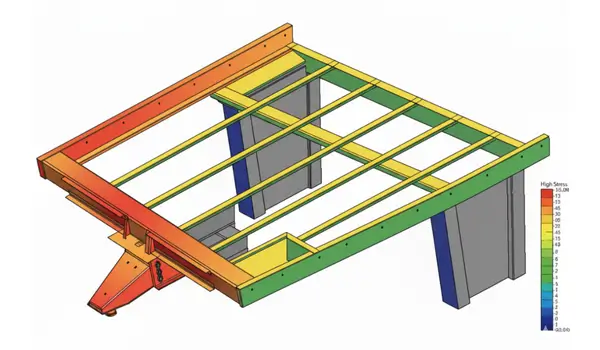

FEA is at the core of the digital engineering approach used by Caliber Technologies. This technique involves simulating the behavior of the upper deck frame and its components under various load conditions using detailed finite element models. These models break the frame down into smaller, manageable elements and allow engineers to predict how the structure will react to a wide range of forces, including bending, torsion, and compression. Through this process, potential weak points in the structure can be identified and addressed early in the design phase. For a 5th wheel towable RV, the upper deck frame is subjected to a wide variety of load cases. These include: Static loads such as the weight of the trailer and the forces transmitted from the tow vehicle during braking and acceleration. Dynamic loads resulting from road imperfections, bumps, and the interactions between the suspension system and the frame. Fatigue loads, which occur over repeated cycles of towing, causing stress to accumulate and potentially leading to structural failure. By running detailed simulations across a range of scenarios, engineers can evaluate the impact of these forces on the upper deck frame’s integrity. Moreover, the multiple load cases help ensure that the frame can handle everything from normal road conditions to extreme usage scenarios.

Nonlinear Static Analysis : Unlike traditional linear static analysis, which assumes that materials behave in a perfectly linear manner under load, nonlinear static analysis accounts for the fact that materials often experience non-linear deformations under large loads. For an upper deck frame, this is crucial as it allows the design to better handle the plastic deformations that may occur during overload conditions or under extreme stresses. This analysis also helps in understanding the strain distribution across the structure, ensuring that no component is overstressed.

Normal Mode and Transfer Path Assessment : While static analysis is essential, the dynamic performance of the RV—particularly the upper deck frame—is equally important. Normal mode analysis provides insight into the natural frequencies and modes of vibration of the structure. By understanding these vibrational characteristics, Caliber Technologies engineers can identify the resonant frequencies of the frame and work to mitigate them. This is particularly important in ensuring that the RV’s ride quality is optimized and that the structure doesn’t amplify harmful road noise and vibrational frequencies.

Furthermore, Caliber employs transfer path analysis (TPA) to evaluate how vibrational energy is transmitted through the structure. This technique allows engineers to design more effectively by improving the damping and stiffness of the frame. This not only results in a smoother ride but also significantly improves the structure’s resistance to road-induced noise, vibration, and harshness (NVH), thus enhancing the overall customer experience.

How Such Models Help

The use of advanced digital engineering models in the design of the upper deck frame helps solve a wide array of structural issues that would be difficult or impossible to address using traditional engineering methods. By simulating the full range of possible load cases and behaviors, Caliber Technologies can optimize every aspect of the upper deck frame, from the architecture of the frame itself to the integration with the rest of the RV structure.

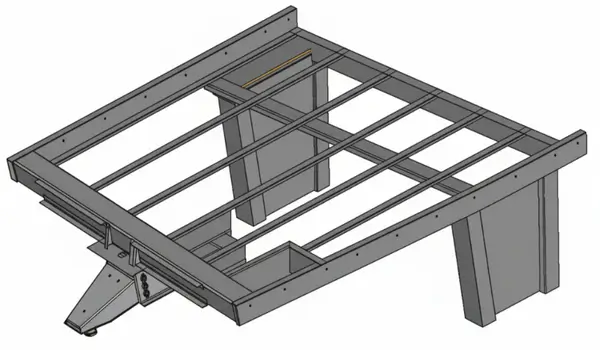

- Optimizing Frame Architecture : One of the most powerful aspects of the FEA-based approach is the ability to evaluate different frame architectures and select the one that best meets the performance and durability targets. For example, by varying the cross-sectional shape of the frame rails or the spacing of cross members, engineers can significantly affect the frame’s stiffness and strength. This process allows for a more efficient design, where only the most critical components are reinforced, rather than over-engineering the entire frame.

- Cross Member and Gusset Integration : Another key feature of the digital engineering approach is the ability to test the addition of cross members, gussets, and welds in the frame design. These features are critical for improving torsional stiffness and distributing forces more evenly across the upper deck frame. By evaluating these components through FEA, Caliber Technologies can determine the optimal placement and size of reinforcements, ensuring the frame is both strong and lightweight.

- Integration with the Superstructure : The upper deck frame does not work in isolation. Its performance is closely tied to the rest of the RV’s superstructure, including the sidewalls, flooring, and roof. The integration between the frame and the superstructure plays a crucial role in meeting the overall stiffness and vibration targets of the entire RV. Caliber Technologies’ digital models allow engineers to evaluate how the frame interacts with these components and identify any potential weaknesses in the connections between them. This holistic approach ensures that the upper deck frame, as well as the rest of the RV, works together as a cohesive and durable unit.

Conclusion

The upper deck frame of a 5th wheel towable RV is a critical structural component that must be designed to withstand dynamic and static loads, manage fatigue, and deliver a high level of performance over the vehicle’s lifetime. The design of this frame is far too complex for traditional engineering methods, and standard calculations do not adequately address the wide range of loading scenarios and dynamic forces that the RV will encounter on the road.

Caliber Technologies’ use of digital engineering tools, including advanced Finite Element Analysis (FEA), nonlinear static analysis, normal mode analysis, and transfer path assessment, allows engineers to design upper deck frames that are stronger, stiffer, and more durable. By simulating a wide variety of load cases and structural configurations, Caliber Technologies optimizes every aspect of the upper deck frame, from material selection to cross-member placement and weld integration. This holistic and iterative process ensures that the frame performs at the highest level of safety, durability, and comfort.

Ultimately, the use of digital engineering techniques in the design of 5th wheel RV upper deck frames not only enhances ride quality but also increases longevity, reduces the likelihood of failure, and improves the overall customer experience. Without these modern techniques, quantifying and addressing these complex structural challenges would be nearly impossible, and the industry would continue to rely on inefficient and costly physical testing.

By embracing digital engineering, Caliber Technologies has established itself as a leader in solving the complex structural challenges of 5th wheel towable RVs, enabling manufacturers to build better, more reliable products faster than ever before.