The leaf spring is one of the oldest yet most enduring components in vehicle suspension systems. Known for its simplicity, strength, and reliability, it continues to play a vital role in commercial vehicles, trucks, and off-road applications. Despite advancements in suspension technologies, the leaf spring remains indispensable for supporting heavy loads and maintaining ride stability.

At Caliber Technologies, we combine Multibody Dynamics (MBD) and Finite Element Analysis (FEA) to help manufacturers design, optimize, and validate leaf spring suspension systems. Our advanced simulation capabilities have helped numerous OEMs and Tier-1 suppliers overcome complex design, engineering, and manufacturing challenges — improving durability, ride comfort, and performance.

1) What Are Leaf Springs?

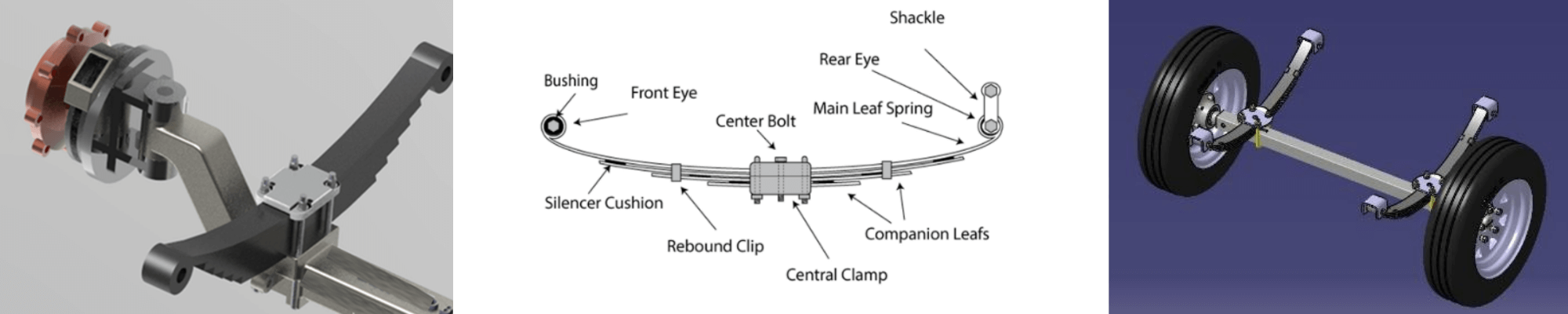

A leaf spring is a simple yet highly effective mechanical component used to absorb shocks and maintain vehicle stability. It consists of multiple layers (“leaves”) of steel plates stacked in a semi-elliptical shape. When subjected to loads or road irregularities, these leaves flex and absorb energy, reducing vibrations transmitted to the chassis.

Leaf springs are commonly used in:

- Commercial trucks and buses for load-bearing capacity.

- Off-road vehicles for durability and articulation.

- Light commercial and utility vehicles for cost-effective suspension performance.

2) Design Principles of Leaf Springs

The performance of a leaf spring depends on its geometry, material properties, and assembly configuration. Key design factors include:

- Leaf thickness and width: Affect stiffness and load-carrying capacity.

- Number of leaves: Determines overall strength and flexibility.

- Camber and curvature: Control ride height and suspension travel.

- Material selection: Influences fatigue life and resistance to failure.

Balancing these parameters is crucial to achieving optimal ride quality and durability — a task that’s best achieved through simulation-driven engineering.

3) Caliber Technologies’ Expertise in Leaf Spring Simulation

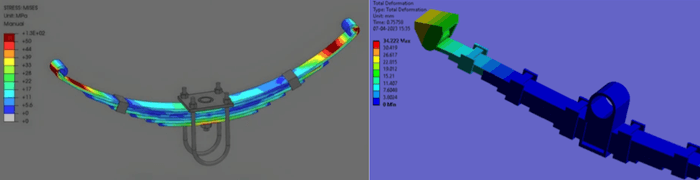

At Caliber Technologies, we leverage MBD and FEA simulations to analyze, validate, and enhance the performance of leaf spring suspensions under real-world conditions.

a) Multibody Dynamics (MBD) Simulation

- Using industry-leading tools such as ADAMS, CarSim, CarMaker, Simpack, and MotionView, our engineers create detailed suspension system models to evaluate:

- Ride and handling characteristics under varying load conditions.

- Dynamic deflection and stress distribution during cornering, braking, or off-road maneuvers.

- Parametric optimization of leaf geometry and stiffness for improved comfort and stability.

b) FEA-Based Structural and Fatigue Analysis

Our Finite Element Analysis (FEA) capabilities complement MBD insights by providing a deeper understanding of structural integrity and failure modes. Using high-fidelity nonlinear and fatigue simulations, we can:

- Predict stress concentrations and potential crack initiation points.

- Evaluate material behavior and surface treatments under cyclic loads.

- Optimize manufacturing parameters such as heat treatment and shot peening to improve fatigue life.

4) Real-World Impact: From Design to Validation

Caliber Technologies has helped several customers across automotive, commercial vehicle, and off-highway sectors solve critical design and performance issues related to leaf spring suspensions.

Examples include:

- Eliminating premature fatigue failures through design re-optimization.

- Improving ride comfort and stability by refining suspension kinematics.

- Reducing prototype testing costs with validated virtual simulation workflows.

Our combination of engineering experience and advanced simulation technology ensures that customers achieve faster development cycles and more reliable suspension systems.

5) The Future of Leaf Spring Design

As the industry shifts toward lightweight materials and electrification, the need for virtual validation is greater than ever. By integrating CAE, MBD, and FEA, Caliber Technologies empowers manufacturers to explore new materials, geometries, and composite leaf spring concepts with confidence — ensuring performance, safety, and durability from the very first iteration.

Conclusion

Leaf springs may be a traditional component, but their design and performance are now enhanced by modern simulation and analysis tools. At Caliber Technologies, our deep expertise in Multibody Dynamics, FEA, and virtual validation allows us to push the boundaries of what’s possible in suspension design.

If your team faces challenges in leaf spring design, durability, or ride performance, our experts can help you model, simulate, and optimize every detail — from concept to production.