The engine piston is at the heart of every internal combustion engine, responsible for converting fuel combustion into useful mechanical power. Its design directly impacts an engine’s performance, efficiency, and durability — making it one of the most critical components in powertrain engineering.

At Caliber Technologies LLC, we specialize in advanced piston design and simulation, combining deep expertise in Multibody Dynamics (MBD), Finite Element Analysis (FEA), and Computational Fluid Dynamics (CFD) to optimize performance across strength, weight, and thermal management. Our engineers perform detailed load analysis, fatigue assessment, and cooling optimization to ensure every piston design delivers the perfect balance of power, reliability, and efficiency.

This blog explores the key principles of piston design, the materials and geometries that drive performance, and how Caliber Technologies applies state-of-the-art virtual engineering to help OEMs and Tier-1 suppliers develop next-generation internal combustion engines.

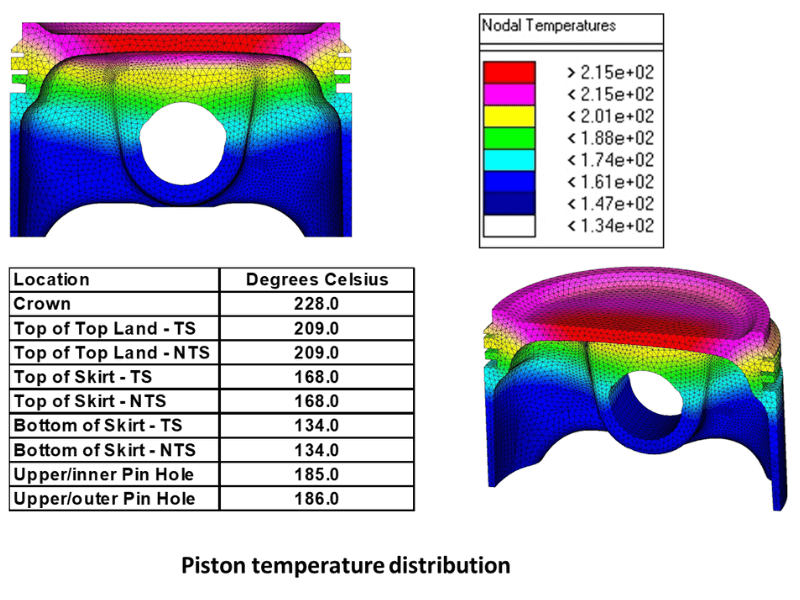

Figure: Temperature Distribution On The Piston

1) The Role of the Piston in Engine Functionality

In an internal combustion engine, the piston moves up and down within the cylinder, compressing the fuel-air mixture and transferring the combustion force to the crankshaft. This reciprocating motion is fundamental to the engine’s operation and affects overall performance, efficiency, and emissions.

2) Key Considerations in Piston Design

When designing engine pistons, engineers must consider several factors:

- Shape and Geometry: The piston shape influences combustion efficiency and heat distribution. Common designs include flat-top, domed, and bowl-in-piston configurations, each with unique performance characteristics.

- Weight: Lightweight pistons reduce the overall mass of the engine, improving responsiveness and fuel efficiency. However, minimizing weight must be balanced with strength and durability.

- Material Selection: Pistons are typically made from aluminum alloys for their excellent strength-to-weight ratio and heat conductivity. Some high-performance applications may use forged aluminum or even steel.

- Thermal Management: Piston designs must account for heat generated during combustion. Effective thermal management strategies, such as cooling channels and coatings, help maintain optimal operating temperatures and prevent deformation.

- Sealing: Piston rings provide a seal between the piston and cylinder wall, preventing gas leakage and ensuring efficient combustion. The design of the rings and their placement is crucial for optimal performance.

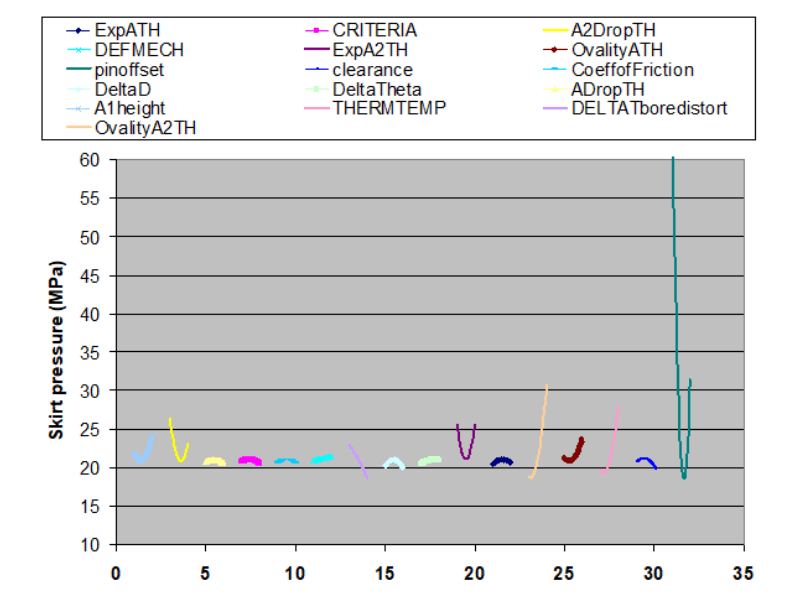

Figure: Piston Design Parameters Sensitivity to Skirt Pressure

3) Innovations in Piston Design

Recent advancements in piston design focus on improving efficiency, reducing emissions, and enhancing performance. Here are some notable innovations:

- Variable Compression Ratio (VCR) Pistons: These pistons can change their compression ratio based on driving conditions, optimizing performance and fuel efficiency across various engine loads.

- Advanced Materials: New materials, such as lightweight composites and specialized alloys, are being developed to enhance piston performance and durability while reducing weight.

- 3D Printing: Additive manufacturing techniques are being explored for producing complex piston geometries that optimize performance and thermal management.

- Surface Treatments: Coatings such as DLC (Diamond-Like Carbon) or ceramic treatments can improve wear resistance and reduce friction between the piston and cylinder walls.

4) Testing and Validation

Designing a piston involves rigorous testing and validation to ensure reliability and performance under real-world conditions. Common testing methods include:

- Finite Element Analysis (FEA): This computational method simulates the piston’s behavior under various loads, helping engineers identify potential failure points and optimize design.

- Dynamometer Testing: Engine dynamometers are used to evaluate the piston’s performance within an engine, measuring power output, efficiency, and emissions.

- Endurance Testing: Long-term testing under simulated operating conditions assesses the piston’s durability and performance over time.

5) Future Trends in Piston Design

As the automotive industry evolves, the design of engine pistons will continue to adapt to new challenges and technologies. Key trends include:

- Electrification: With the rise of electric vehicles (EVs), piston design may pivot towards hybrid engines, where pistons must accommodate new fuel types and combustion methods.

- Sustainability: There is a growing emphasis on designing pistons that enhance fuel efficiency and reduce emissions, aligning with global sustainability goals.

- Smart Technologies: Integrating sensors into piston designs could provide real-time data on performance metrics, allowing for predictive maintenance and optimization during operation.

Conclusion

Engine piston design is a complex and critical aspect of automotive engineering that directly impacts engine performance and efficiency. By understanding the key considerations and innovations in piston design, engineers can create solutions that meet the demands of modern vehicles. As technology continues to advance, the future of piston design promises exciting opportunities for enhancing engine performance and sustainability. Let’s talk piston at operations@thecalibertech.com.