Introduction

Caliber Technologies LLC (Caliber Tech) conducted a comprehensive simulation-based engineering study to assess the structural integrity of a motorhome roof system in accordance with FMVSS 220 – School Bus Rollover Protection standards. The study utilized a high-fidelity nonlinear Finite Element Analysis (FEA) model that accurately represented the geometry, material behavior, and boundary conditions of the roof structure and supporting chassis beams.

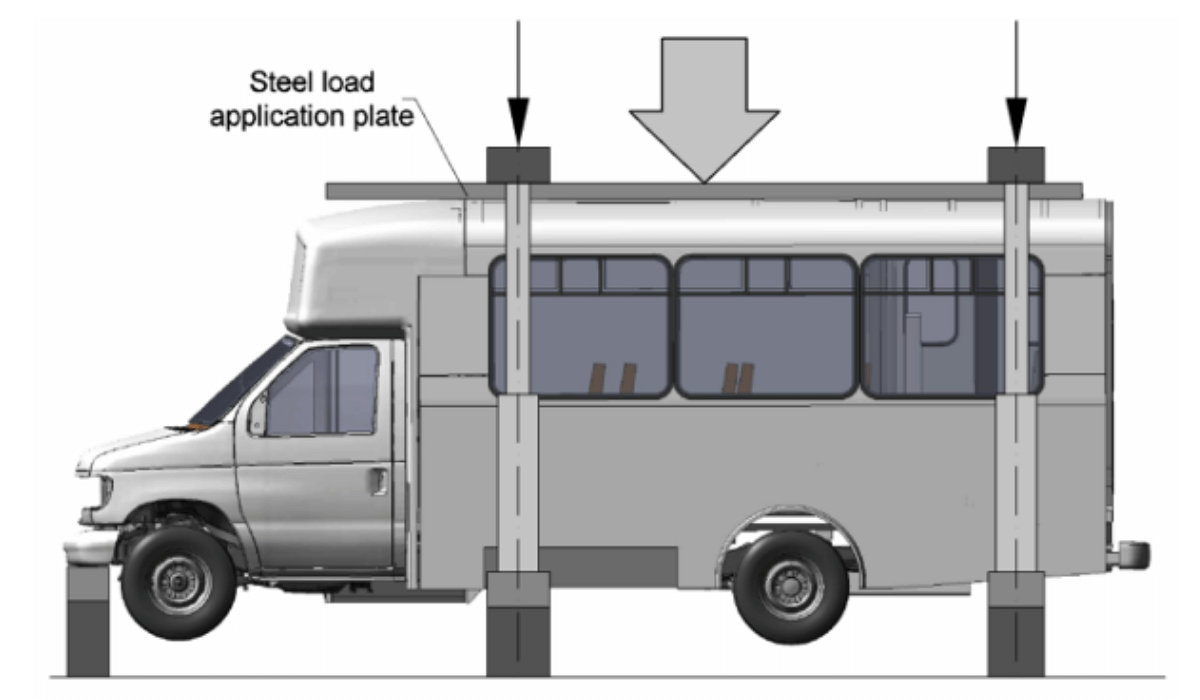

The primary objective of the analysis was to replicate the FMVSS 220 quasi-static roof crush test within a virtual simulation environment. The FEA model incorporated the prescribed preload (2,227 N) and the 1.5× Unloaded Vehicle Weight (UVW) quasi-static loading applied through a rigid rectangular plate. Structural supports and constraints were modeled to replicate the physical test configuration, while nonlinear material and contact definitions were applied to simulate realistic deformation behavior.

This study provided detailed insights into roof deformation patterns, load-deflection characteristics, and stress distribution across critical structural members. The results serve as a decision-support tool for engineers involved in vehicle body development, providing a validated methodology for assessing compliance, optimizing design stiffness, and preparing for regulatory physical testing.

Reference Standard – FMVSS 220 Test Procedure

During the test, an initial preload of 2,227 N (500 lbf) was applied to the structure to eliminate any slack prior to the main loading sequence. The primary load was set at 1.5 times the unloaded vehicle weight (UVW), providing a rigorous assessment of the roof’s strength. The chassis beams were rigidly fixed to the base, and suspension compliance was not considered, ensuring a controlled boundary condition. Load was introduced as a uniform pressure using a flat, rigid rectangular plate, with the rate of application maintained at or below 12.7 mm/s (0.5 in/s).

The acceptance criteria specified that the maximum allowable roof deformation was 130.2 mm (5.125 in), and all emergency exits had to remain operable throughout and after the loading cycle. The simulation model was built to closely adhere to these conditions, ensuring that computational predictions would be directly comparable to outcomes from potential physical tests.

Simulation Execution

The analysis was performed using a nonlinear static solver capable of handling geometric and material nonlinearities. Several iterations were performed to assess the effects of mesh refinement on peak deflection, Sensitivity to load application rate and boundary constraint stiffness, and Convergence stability across nonlinear solution phases. The model demonstrated stable and repeatable load-deflection responses throughout the simulation process.

Post-Processing and Results

1) Global Roof Deformation

The maximum roof deformation was recorded at the center region beneath the loading plate. Peak deformation levels were found to be within the FMVSS 220 limit of 130.2 mm, confirming that the structure satisfied the global stiffness and strength criteria.

Deformation contour plots indicated a uniform load transfer through the roof bows and side rail structures, with localized bending occurring between bow members.

2) Stress and Strain Analysis

Stress maps revealed that the critical stress concentrations occurred at the junctions between roof bows and vertical pillars. Plastic yielding initiated locally but remained contained, demonstrating stable load redistribution without structural collapse.

The plastic strain contours confirmed that high-stress regions were well below material failure limits, validating the design’s safety margin.

3) Load-Displacement Behavior

The force-displacement response curve exhibited a characteristic nonlinear trend typical of quasi-static roof crush events. The initial stiffness phase was followed by a gradual yielding phase, and a stable post-yield response indicated effective energy absorption capability.

4) Emergency Exit Operability

Post-processing evaluations of door and window frame geometries demonstrated that all clearances remained within acceptable limits, maintaining emergency exit operability after load removal.

5) Discussion and Engineering Insights

The completed FMVSS 220 virtual test demonstrated the structural adequacy of the roof system under the defined loading conditions. The nonlinear simulation provided critical insight into:

- Load path efficiency and deformation modes.

- Effectiveness of local reinforcements.

- Material utilization and yield initiation zones.

The results indicated that the structure met the required stiffness and deformation limits, with potential for targeted improvements in high-stress joint regions.

The analysis also confirmed that a simulation-driven approach offers substantial benefits in reducing physical test iterations, identifying potential design weaknesses early, and supporting weight optimization while maintaining compliance.

Recommendations

Based on the study results, Caliber Technologies identified several design optimization opportunities:

- Introduce local reinforcement at critical weld junctions to reduce stress localization.

- Optimize roof bow spacing and cross-section geometry for stiffness-to-weight efficiency.

- Validate the simulation model through correlation with physical testing data to further refine predictive accuracy.

Conclusion

Caliber Technologies successfully executed a nonlinear finite element simulation of a motorhome roof system subjected to FMVSS 220 roof crush loading. The results demonstrated compliance with the deformation and operability requirements of the standard, validating the structural adequacy of the design.

This study underscores Caliber Technologies’ expertise in applying advanced FEA methodologies for complex vehicle structures, enabling customers to achieve compliance, reduce development costs, and accelerate product validation cycles through simulation-driven engineering.