Designing frames for demanding applications—such as truck, trailer, RV, and travel trailer chassis—requires a delicate balance between load carrying capacity, weight, stiffness, and manufacturability. Let’s break down the main engineering challenges, then see how Computer-Aided Engineering (CAE) methods, especially Finite Element Analysis (FEA), are crucial in overcoming them.

Caliber Technologies specializes in advanced frame design analysis using industry-leading Finite Element Analysis (FEA) tools including Abaqus, Ansys, and Hypermesh. This article demonstrates how our experts leverage FEA to optimize truck, trailer, travel trailer, and RV frames—ensuring structural integrity, compliance, and lightweight efficiency for demanding real-world applications.

Advanced FEA Techniques and Workflow

Our technical team begins each project by translating frame concepts into high-fidelity digital models, typically built with CAD and prepared using hypermesh preprocessing. Material properties and manufacturing constraints are selected and validated against application specifications—for example, high-strength steel alloys for truck frames or aluminum grades for RV frames. We perform both linear and nonlinear analyses to capture the range of stresses, strains, and deformations expected during service, ensuring compliance with safety factors and regulatory standards.

FEA software is selected based on the complexity of the design and project goals:

- Abaqus excels at nonlinear response simulation and multi-material contact scenarios.

- Ansys provides robust modal, fatigue, and static/dynamic analyses for frame vibration and crash simulations.

- Hypermesh offers powerful preprocessing for large assemblies and integration with various solvers for rapid design iteration.

The following are key considerations in designing frames for various applications.

| Design Aspect | Challenge | Key Technical Issues |

| Load Carrying Capacity | The frame must safely support all expected static and dynamic loads, including cargo, passenger, braking, and cornering forces. Failures can include yielding, buckling, or global collapse. | – Predicting maximum load conditions (dead, live, crash) – Efficient material placement (I-beams, box sections) – Avoiding local (buckling) and global (instability) failure modes |

| Weight Optimization | Reducing structural weight while maintaining safety, stiffness, and fatigue life to improve payload capacity, efficiency, and fuel economy. | – Balancing strength and mass in critical stress regions – Material and geometry sensitivity (HSS, aluminum alloys) – Topology optimization through FEA to remove low-stress material |

| Stiffness Optimization | Ensuring the frame resists deflection, vibration, and roll under operational loads while maintaining comfort, control, and long-term durability. | – Managing torsional and bending stiffness levels – Preventing resonance using modal analysis – Iterative refinement using FEA for structure–mass tradeoff |

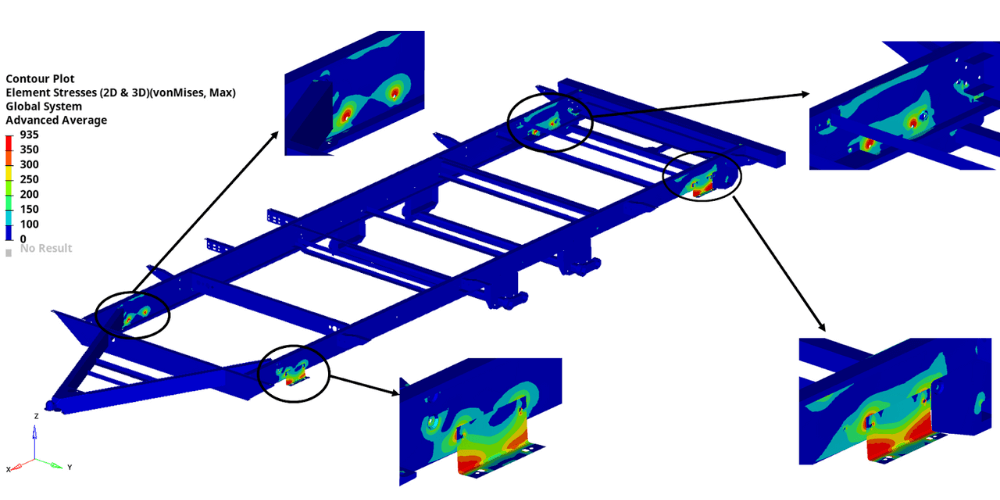

| Weld Optimization | Welded joints act as localized weak links, prone to fatigue cracking and stress accumulation if not properly designed. | – Modeling welds with realistic local loading distributions – Fatigue and crack propagation analysis via submodeling – Refinement of weld geometry, material, and process parameters to balance structural efficiency and manufacturability |

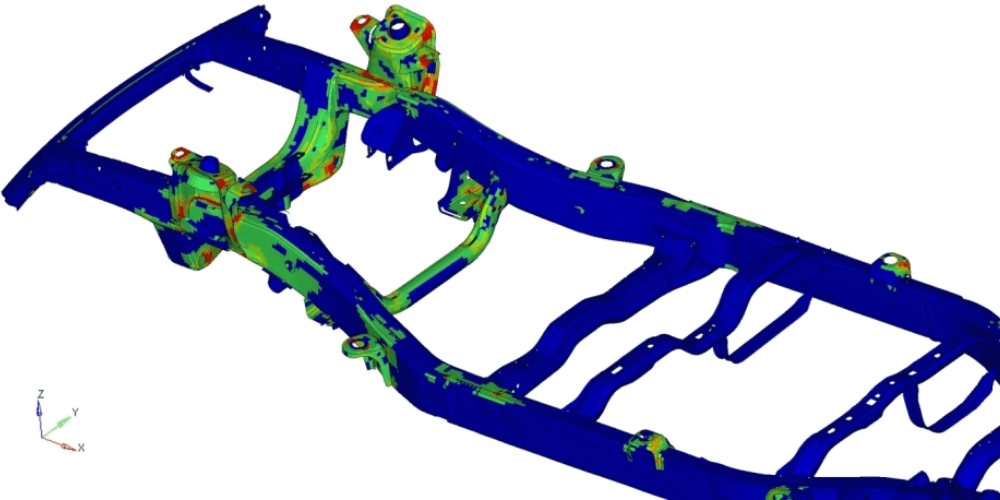

Example 1: Truck Frame Optimization

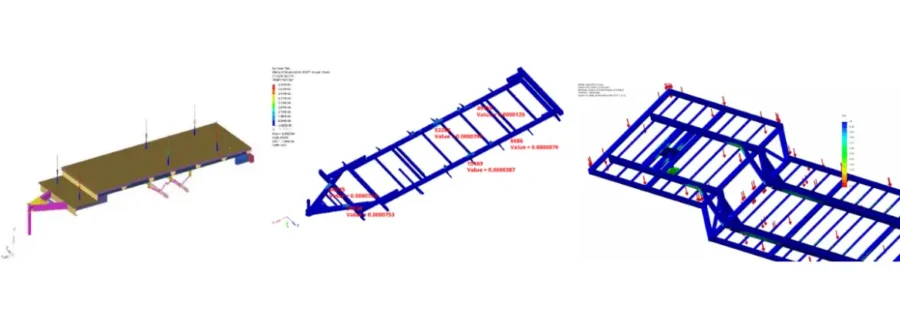

In a recent engagement, Caliber Technologies analyzed a truck chassis frame supporting multiple loads from the drivetrain, suspension, and superstructure. Using Ansys, we simulated the frame under vertical, torsional, and lateral loading conditions, evaluating both stress distribution and deformation patterns throughout key regions such as cross-members and side rails. Modal analysis identified natural frequencies to avoid resonance with road-induced vibrations. Our optimization workflow reduced weight by 12% while maintaining a safety factor above regulatory requirements.

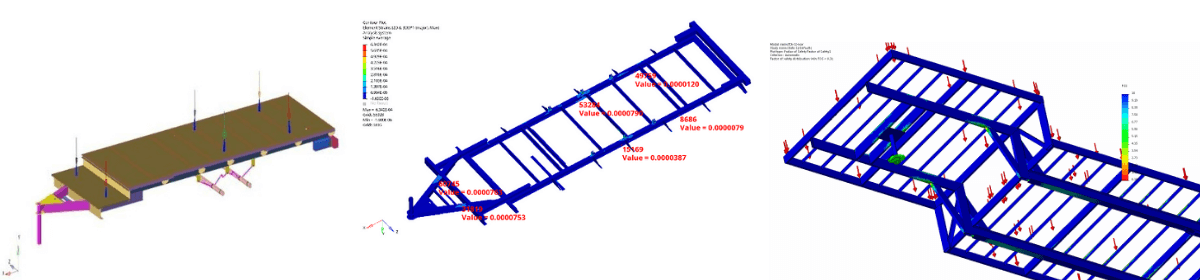

Example 2: Travel Trailer Frame Verification

For a travel trailer manufacturer, we used Abaqus coupled with Hypermesh to validate the integrity of innovative cross-braced aluminum frame designs. Parametric FEA studies were performed to assess the impact of varying bracing configurations. Results confirmed that both the traditional and new design exceeded static and dynamic strength criteria, with fatigue analysis ensuring durability over rough terrain. The simulation-driven approach reduced prototype iterations and cut lead time by 30%.

Why Choose Caliber Technologies for FEA Analysis?

- Deep automotive and commercial vehicle expertise: From OEM truck chassis to bespoke RV frames.

- Proven ability to deliver robust, manufacturable designs that excel under real operating conditions.

- Seamless integration with customer workflows and design targets, leveraging advanced FEA, CFD, and system-level engineering for optimal solutions.

Discover more about Caliber Technologies’ frame analysis capabilities and how simulation-driven engineering can accelerate innovation while managing cost, compliance, and reliability for complex vehicle platforms.