Industrial robots are the backbone of modern manufacturing, enabling high-precision, repetitive tasks across automotive, electronics, consumer goods, and many other sectors. However, repeated operation under dynamic loads can lead to structural deflection, fatigue, and eventual component failure, directly impacting productivity, safety, and equipment lifespan. At Caliber Technologies LLC, we leverage Finite Element Analysis (FEA) to predict, optimize, and validate robotic arm performance under these demanding conditions.

Understanding Robot Arm Structural Challenges

Robot arms are subjected to a variety of mechanical stresses during operation. Continuous pick-and-place motions, welding, assembly, or material handling generate cyclic loads, bending moments, torsional stresses, and vibration throughout the arm structure. Even small deflections at the end effector can lead to positional inaccuracies, affecting product quality. Over time, repetitive stresses can cause fatigue damage in critical joints, linkages, and mounting points, potentially leading to costly downtime and maintenance.

Designing a robot arm that balances strength, stiffness, and durability while minimizing weight and energy consumption requires a simulation-driven approach. Physical prototyping alone is often insufficient to capture the nuanced load paths and localized stress concentrations experienced over thousands or millions of cycles.

Technical Approach

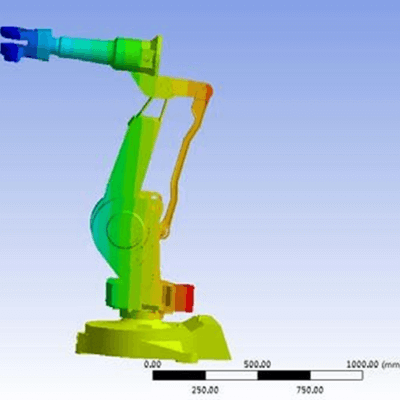

At Caliber Technologies, we adopt a physics-based FEA workflow to ensure robot arms are structurally robust and fatigue-resistant. Our engineers start by creating detailed 3D CAD models of the robotic arm, including all links, joints, actuators, and end-effectors. Material properties, contact interactions, and boundary conditions are accurately defined to replicate real-world operational scenarios. We simulate dynamic loads, bending moments, torsional forces, and payload interactions across the entire range of robot motion. This allows us to quantify deflection at the end effector and evaluate how structural flexibility affects positioning accuracy and repeatability.

- Stress and Strain Distribution: FEA enables identification of critical regions where stress concentrations occur, such as joints, welds, mounting points, and actuator interfaces. This insight guides targeted reinforcement, material selection, or geometry adjustments to enhance structural integrity.

- Fatigue and Lifecycle Prediction: Repetitive tasks induce cyclic loading, which can reduce the operational life of robotic components. Using advanced fatigue analysis, we predict lifetime cycles, damage accumulation, and potential failure points, ensuring that the robot arm meets long-term durability requirements.

- Design Optimization: Through iterative FEA simulations, we optimize the arm geometry, material selection, and joint design to minimize weight while maximizing stiffness and fatigue resistance. This results in energy-efficient, high-performance robotic arms capable of sustained operation in demanding manufacturing environments.

Benefits of FEA-Driven Robot Arm Design

By applying advanced FEA techniques, Caliber Technologies enables clients to achieve:

- Reduced Deflection: Ensuring end-effector precision under full payload and motion cycles.

- Extended Fatigue Life: Designing joints and links to withstand millions of repetitive cycles.

- Optimized Weight and Material Usage: Achieving lightweight designs without compromising strength.

- Predictable Performance: Minimizing downtime and maintenance through robust simulation validation.

- Faster Development Cycles: Reducing reliance on physical prototypes with high-fidelity virtual validation.

Conclusion

Designing industrial robot arms that can endure repetitive tasks without structural compromise requires a combination of advanced FEA, dynamic load simulation, and fatigue analysis. Caliber Technologies provides end-to-end capabilities in structural simulation, helping manufacturers optimize robot arm designs for precision, durability, and long-term reliability. By leveraging simulation-driven engineering, clients can deliver robust robotic systems capable of high-performance operation in challenging industrial environments.