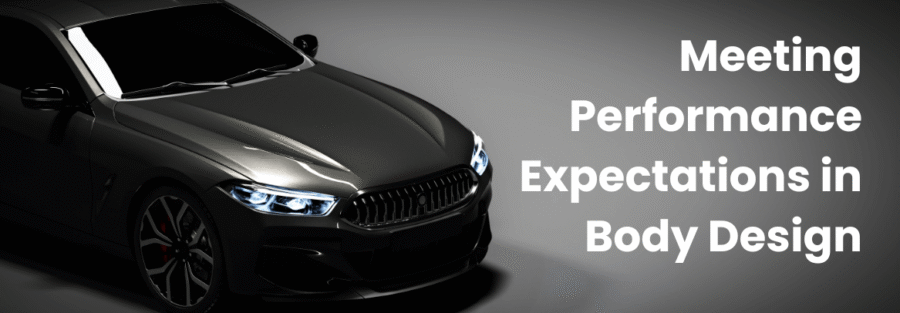

Body design, particularly the Body-in-White (BIW) stage, plays a pivotal role in achieving key performance targets like static and dynamic stiffness, Noise, Vibration, and Harshness (NVH), crashworthiness, and durability. Engineering such complex structures demands sophisticated simulation tools and analysis strategies to ensure safety, comfort, and longevity.

Technical Challenges in Body Design

| Performance Aspect | Description | Technical Challenges |

| Static Stiffness | Ability to resist deformation under steady load conditions, such as bending and torsion | Simulating realistic load cases and identifying localized weak points that cause excessive deflection |

| Dynamic Stiffness | Resistance to vibration-induced deformation under transient operational loads | Capturing transient dynamic responses and mode shapes to prevent resonance and amplify NVH effects |

| Noise, Vibration, and Harshness (NVH) | Managing structural vibrations and resonances that cause noise and discomfort | Identifying natural frequencies and designing structural modifications to avoid excitations by operational sources |

| Crashworthiness | Capacity to absorb impact energy safely through plastic deformation | Modeling large deformations, material nonlinearity, and energy absorption pathways accurately under crash scenarios |

| Durability | Ensuring long-term fatigue resistance under cyclic loading, especially at welds and joints | High-fidelity fatigue life prediction and stress concentration analysis at critical locations |

The Role of Normal Mode Analysis in Modal Management for NVH

Importance of Normal Mode Analysis

Normal mode (modal) analysis finds the natural frequencies and mode shapes of the body structure. Identifying these modal parameters enables engineers to:

- Predict potential vibration and resonance problems early in design.

- Design structural reinforcements or mass-tuning to shift problematic modes away from excitation frequencies.

- Optimize damping and joint stiffness to control vibration amplitudes.

Modal management ensures that operational frequencies from engines, road inputs, and other sources do not coincide with natural body modes, reducing NVH issues comprehensively.

Caliber Technologies’ Advanced CAE Capabilities for Body-in-White Analysis

At Caliber Technologies, we employ state-of-the-art CAE tools like Abaqus, Ansys, and Hypermesh to perform:

- Static stiffness simulations evaluating bending and torsion under realistic load cases to identify weak points and optimize cross sections.

- Modal analysis to extract normal modes and frequencies through high-fidelity FE models of BIW components, guiding modal tuning.

- Crash simulations with nonlinear dynamic solvers capturing plasticity and energy absorption behavior.

- Fatigue and durability assessments using detailed stress-life and strain-life approaches at weld seams and high-stress zones.

- Multiphysics coupling, integrating thermal and vibration analyses for comprehensive performance prediction.

Our expertise enables rapid iterative design optimization, minimizing physical prototypes and accelerating time to market.

Detailed Examples

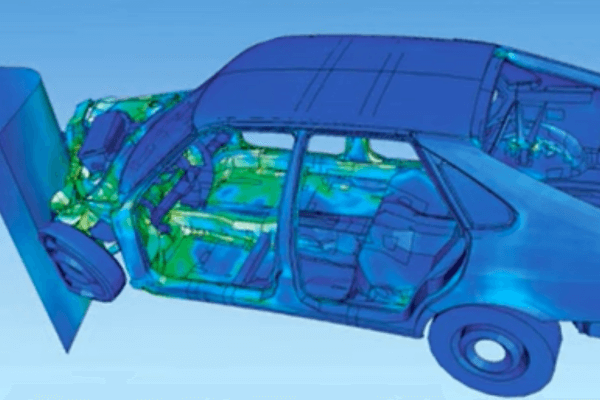

Example 1: Automotive Body-in-White Stiffness and NVH Optimization

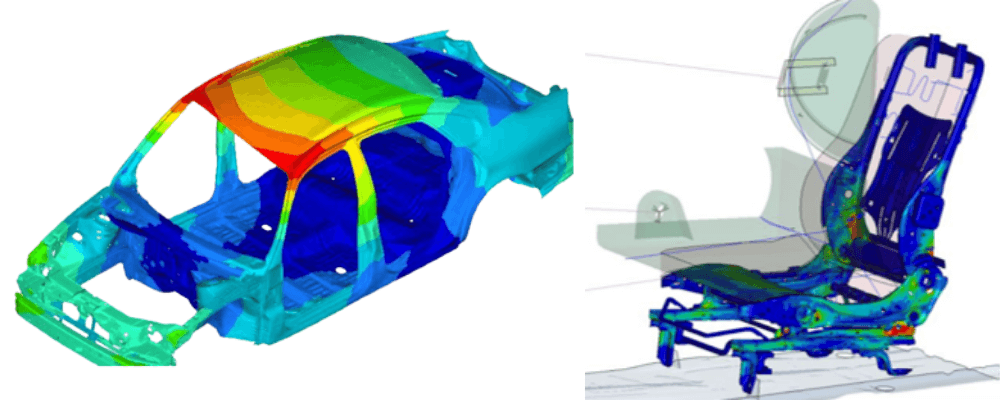

For a new passenger vehicle BIW design, Caliber engineers constructed a detailed finite element model incorporating shell and beam elements representing welded steel panels and reinforcements. Static load cases simulated vertical bending via rocker loads and torsion via shock tower twisting moments. We quantified stiffness metrics and identified localized deformations signaling potential NVH hotspots.

Next, modal analysis revealed natural frequencies near engine firing harmonics. Guided by these insights, design refinements included strategically placed gussets and adjusted panel thicknesses, which shifted natural frequencies away from excitation cycles. Subsequent NVH performance improved significantly, verified through physical modal testing correlation.

Example 2: Industrial Machinery Frame Modal and Durability Assessment

Caliber Technologies applied advanced CAE methods to analyze a large industrial machinery frame used in manufacturing equipment. The frame required high stiffness to support heavy operational loads and dynamic forces while minimizing vibrations transmitted to sensitive components.

Using FE modal analysis, engineers identified critical bending and torsional natural modes that could resonate with machine cycle frequencies, causing noise and excessive wear. Structural modifications guided by this modal management reduced resonance risks substantially. Durability simulations under cyclic industrial loading identified stress concentration areas around weld joints and mounting points, enabling targeted reinforcement to improve fatigue life and reduce maintenance downtime.

Interested in leveraging advanced CAE for your body structure challenges? Caliber Technologies delivers tailored simulation solutions that empower confident, data-driven engineering decisions across automotive and industrial sectors. Let’s talk body design at operations@thecalibertech.com.