Introduction and Background

Modern recreational vehicle (RV) customers expect more than just mobility—they expect automotive-grade comfort and climate control. Whether camping in Arizona’s summer heat or parked on a coastal highway, the interior of an RV must remain cool, comfortable, and energy-efficient under a wide range of environmental conditions.

Maintaining such comfort is far from simple. Unlike stationary buildings, RVs operate in dynamic, outdoor environments where solar radiation, air leakage, material conductivity, and airflow distribution constantly interact. The confined interior spaces and diverse layouts—bedrooms, living areas, slide-outs, and lofts—make uniform temperature control challenging.

Many RVs struggle with common thermal performance issues, including:

- Uneven cooling—with hot spots near large windows or slide-outs.

- Overloaded A/C units, unable to maintain set temperature in extreme heat.

- Poor duct design, leading to low airflow in remote cabin zones.

- Excessive wall and roof heat gain, particularly in units with dark exteriors or low insulation value.

Customers experiencing these issues often perceive the RV as poorly engineered, even if the underlying cause lies in inefficient thermal design rather than HVAC capacity. As the RV industry evolves toward more energy-efficient, comfort-focused designs—especially with electric RVs and off-grid capable systems—a data-driven approach to thermal management is becoming essential.

This is where Caliber Technologies provides critical value. Using advanced Computational Fluid Dynamics (CFD) simulations, Caliber enables RV manufacturers to analyze, predict, and optimize their vehicles’ thermal performance digitally—long before physical testing.

The Need for Thermal CFD Analysis in RV Design

Traditional HVAC and insulation design methods for RVs rely heavily on empirical testing or supplier recommendations for A/C sizing and duct layout. While functional, these approaches fail to capture the complex thermal and airflow interactions inside the RV cabin.

Some key challenges that make CFD-based analysis essential include:

- Solar loading from large surface areas exposed to direct sunlight.

- Multi-zone temperature control, where bedroom, living area, and galley zones must be conditioned simultaneously.

- Varying wall materials and insulation properties, which influence heat conduction and radiation.

- Compact and irregular airflow pathways, where ducts bend, split, and terminate near obstructions.

- Dynamic boundary conditions, such as outdoor air temperature, solar position, and humidity levels.

Without a digital model to analyze these effects holistically, even a well-sized A/C unit may fail to deliver uniform comfort. A CFD-based approach helps RV OEMs understand why certain regions overheat, how air moves through ducts and vents, and what changes improve overall efficiency.

Caliber Technologies’ CFD-Based Thermal Engineering Approach

Caliber Technologies employs a rigorous, multi-physics approach to model and optimize the thermal and airflow behavior of RV interiors. By combining Computational Fluid Dynamics (CFD) with heat transfer and radiation modeling, our engineers provide detailed insight into how temperature, airflow, and material choices interact inside the cabin environment.

Geometry and Model Setup

Caliber begins by creating a 3D digital model of the RV interior, including the:

- A/C unit and duct system, with accurate geometry for vents, outlets, and returns.

- Cabin layout, including partitions, furniture, and heat sources (appliances, lighting, occupants).

- Exterior shell, with materials assigned realistic thermal conductivity, emissivity, and reflectivity values.

Each surface and duct wall is modeled with realistic boundary conditions, such as:

- Ambient temperature (e.g., 38–45°C for summer peak).

- Solar radiation intensity and direction, based on geographic and time-of-day conditions.

- Internal heat gains from people and electronics.

This allows Caliber to recreate realistic “peak summer” test conditions virtually, simulating scenarios that are expensive or time-consuming to reproduce in physical prototypes.

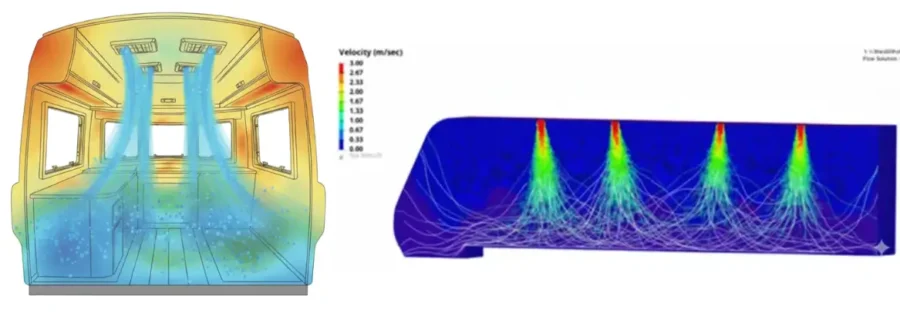

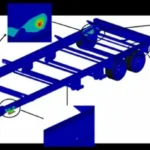

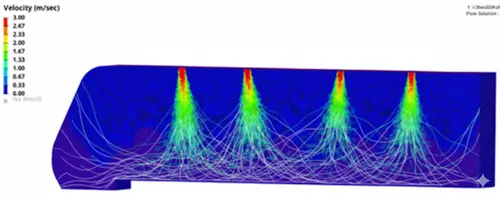

Airflow Analysis and Duct Optimization

Using CFD, Caliber analyzes airflow distribution throughout the RV cabin. The results highlight:

- Velocity profiles to show air movement and stagnation zones.

- Temperature gradients to identify undercooled or overheated areas.

- Pressure losses in ducts and vents, indicating potential flow inefficiencies.

Based on these results, engineers can optimize:

- Duct routing and sizing to ensure balanced flow.

- Vent placement for uniform temperature distribution.

- Air return locations to improve circulation and avoid short-circuiting cool air.

The goal is to achieve consistent airflow and temperature uniformity in all living spaces with minimal power consumption.

Thermal Insulation and Material Optimization

Caliber Technologies also evaluates how different wall, roof, and floor materials influence thermal performance.

Using conjugate heat transfer (CHT) modeling, engineers simulate the heat transfer through multilayer materials—such as aluminum skins, plywood substrates, foam insulation, and interior linings.

This analysis helps determine:

- Optimal insulation thickness and thermal resistance (R-value).

- Best reflective coatings or surface finishes to reduce radiant heat gain.

- Material trade-offs between thermal protection, weight, and cost.

CFD-derived data quantifies how each material choice affects cabin temperature rise over time and A/C energy load during operation.

Radiation and Solar Heat Load Modeling

Unlike conventional heat transfer analysis, Caliber incorporates radiative heat transfer from sunlight into the CFD simulation.

By using solar ray-tracing models, we can evaluate:

- How direct and diffuse sunlight affects wall and roof temperatures.

- The impact of window orientation and tinting on cabin heat gain.

- How paint color and reflectivity influence overall solar absorption.

For example, a dark-colored RV roof may reach 75°C in direct sun, while a reflective white or silver finish might stay under 55°C—resulting in significantly lower A/C load.

These simulations help OEMs make evidence-based design decisions on coatings, roof vents, and window configurations that reduce total heat ingress.

A/C Sizing and System Performance Validation

Once airflow and material optimizations are complete, Caliber uses CFD results to validate A/C system performance for different operating conditions.

The digital model predicts:

- Cooling rate and time to reach steady-state temperature.

- Power consumption vs. cooling effectiveness.

- Effect of different A/C capacities (BTU ratings) on comfort.

- Duct and vent temperature differentials, ensuring every zone receives sufficient cooling.

This data allows RV manufacturers to select the right A/C unit size—neither underpowered (leading to poor comfort) nor oversized (increasing cost and energy consumption).

Benefits of Caliber Technologies’ CFD-Driven Approach

Caliber Technologies’ simulation-based thermal analysis provides a series of measurable benefits for RV OEMs:

| Benefit | Description |

| Optimized Comfort | Even temperature distribution across all zones—eliminating hot spots and undercooled regions. |

| Reduced Development Time | Fewer physical prototypes required for A/C and duct validation. |

| Energy Efficiency | Correctly sized A/C and improved insulation lower energy use and generator load. |

| Material Optimization | Data-driven material selection for walls and roofs based on insulation and solar reflectivity. |

| Customer Satisfaction | Improved climate control enhances comfort and perceived quality, reducing complaints. |

| Performance Validation | Digital simulation provides verifiable evidence of thermal compliance under extreme conditions. |

By integrating thermal CFD modeling early in the product design cycle, OEMs can make informed design choices that balance performance, cost, and manufacturability.

Case Example: Holistic Thermal Optimization Process

A typical Caliber Technologies thermal optimization program for an RV manufacturer includes:

- Baseline CFD Analysis – Simulate the current RV design under peak summer conditions to identify thermal inefficiencies.

- Design Iterations – Evaluate alternate duct layouts, insulation upgrades, and surface coatings.

- A/C Capacity Study – Compare different unit capacities and their impact on steady-state cabin temperature.

- Validation Simulation – Re-run optimized configuration under variable sun angles and ambient conditions.

- Supplier Collaboration – Work with HVAC suppliers to implement final duct geometries and air distribution systems.

This process yields a robust, data-validated HVAC configuration that performs optimally across real-world use scenarios.

Conclusion

Delivering thermal comfort in an RV is a multidimensional challenge that involves far more than simply installing a powerful air conditioner. It requires a deep understanding of airflow dynamics, material heat transfer, and solar radiation effects—all working together to maintain a stable interior climate.

Caliber Technologies brings advanced CFD-based thermal modeling and simulation to the RV industry, helping manufacturers design vehicles that remain cool, efficient, and comfortable even in extreme environments.

Through its integrated digital engineering approach, Caliber Technologies enables OEMs to:

- Optimize A/C performance and duct design,

- Select the right materials and coatings for thermal insulation, and

- Validate comfort and efficiency through quantitative simulation results.

By leveraging CFD, RV manufacturers can move from trial-and-error development to predictive engineering, creating products that delight customers with superior comfort, energy efficiency, and reliability.