In modern vehicles, cabin comfort is more than a luxury — it’s a critical differentiator that shapes customer satisfaction, vehicle refinement, and overall driving experience. From achieving uniform airflow distribution to ensuring rapid defrosting of windshields in cold conditions, HVAC (Heating, Ventilation, and Air Conditioning) systems play a vital role in passenger comfort and safety.

At Caliber Technologies, we leverage advanced Computational Fluid Dynamics (CFD) simulations to analyze and optimize vehicle HVAC and cabin comfort systems — delivering insights that guide better design decisions, faster development cycles, and superior real-world performance.

Understanding HVAC CFD and Cabin Comfort Simulation

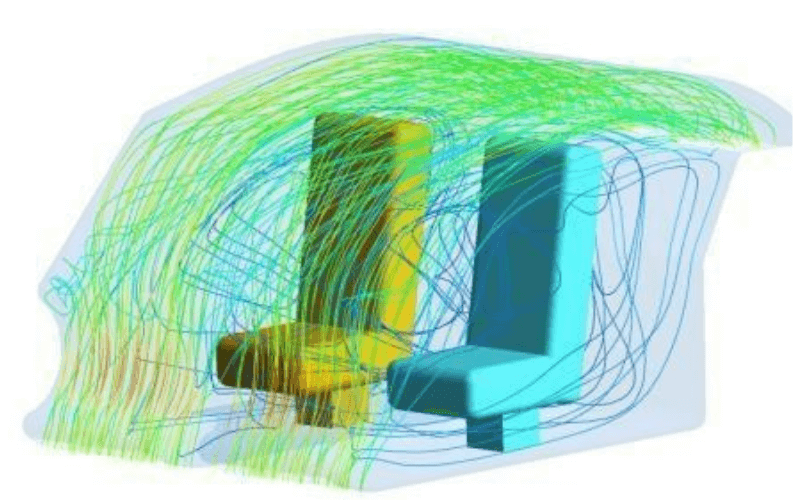

HVAC CFD involves creating a detailed virtual model of the vehicle cabin and simulating how air and heat move within that space. By replicating physical airflow, temperature gradients, and transient thermal effects, engineers can study passenger comfort and HVAC system efficiency long before a prototype is built. Key objectives of cabin comfort simulations include:

- Airflow distribution analysis: Evaluating how effectively conditioned air reaches all zones of the cabin.

- Defrost and demist performance: Ensuring rapid and uniform clearing of windshields and side windows.

- Thermal comfort mapping: Quantifying passenger comfort through temperature and velocity contour plots.

- HVAC duct optimization: Minimizing pressure drops and improving fan efficiency for quieter and more energy-efficient systems.

Caliber Technologies’ CFD Expertise

With extensive experience in automotive CFD, Caliber Technologies has supported OEMs and Tier-1 suppliers in developing high-performance HVAC systems through a deep understanding of airflow physics, transient behavior, and cabin thermodynamics. Our capabilities include:

- HVAC Duct and Airflow Modeling

We create detailed 3D models of HVAC ducts, vents, and diffusers using parametric geometry and simulate steady-state and transient airflow under varying fan speeds, flap positions, and ambient conditions. This allows us to identify flow separation zones, recirculation regions, and uneven air distribution, leading to better duct routing and design.

- Transient Airflow and Thermal Comfort Simulation

Using advanced transient CFD analysis, we evaluate how airflow and temperature evolve over time within the cabin — especially during start-up or defrost cycles. This enables prediction of passenger thermal comfort (PMV, PPD indices) and identification of delays or inefficiencies in achieving desired cabin temperature targets.

- Comfort and Defrost Performance Mapping

We use comfort mapping techniques to visualize temperature and velocity distributions across seating zones, ensuring that passengers in all rows receive consistent comfort levels. Our defrost optimization simulations analyze heat transfer between the air jets and windshield surface to guarantee rapid visibility recovery under cold weather conditions.

- Co-Simulation with Control Systems

Caliber’s multidisciplinary team integrates CFD results with 1D system models or control logic (for example, in Simulink or Amesim) to create a digital twin of the HVAC system. This enables virtual calibration and performance prediction across various operational modes before physical testing.

Benefits of CFD-Driven HVAC Development

By employing CFD early in the vehicle design phase, Caliber Technologies helps clients:

- Reduce prototype iterations through virtual validation of airflow and comfort performance.

- Shorten development time by evaluating multiple design concepts rapidly.

- Enhance energy efficiency by optimizing duct geometry and fan power consumption.

- Improve passenger comfort using data-driven insights into airflow and temperature distribution.

- Validate defrost performance to meet safety and regulatory standards.

- Driving Cabin Comfort with Simulation Expertise

At Caliber Technologies, we combine engineering experience, advanced CFD modeling, and deep knowledge of vehicle thermal systems to deliver actionable insights for HVAC system design and optimization. Our simulation-driven approach ensures that every airflow path, vent design, and duct contour contributes to a quiet, comfortable, and efficient cabin environment.

Whether you are developing a new HVAC architecture, enhancing cabin comfort, or resolving airflow issues, Caliber Technologies acts as an extension of your engineering team — providing the bandwidth and expertise to bring simulation precision to every stage of design and validation.