Trailer hitches are a critical component of vehicle towing systems, directly influencing safety, durability, and performance. Designing a robust hitch requires careful consideration of dynamic loads, structural integrity, and long-term reliability. At Caliber Technologies LLC, we specialize in leveraging Finite Element Analysis (FEA) to develop high-performance hitch designs that comply with SAE J684 standards, ensuring optimal safety and functionality for all types of trailers and towing vehicles. This includes a wide variety of trailers such as:

- Utility trailers

- Boat trailers

- Camping and travel trailers

- Special-purpose trailers

The SAE J684 standard governs couplings, hitches, and safety chains for trailers with a Gross Vehicle Weight Rating (GVWR) not exceeding 4,540 kg (10,000 lb). This encompasses utility trailers, boat trailers, camping and travel trailers, and special-purpose trailers, typically towed by passenger cars, light-duty commercial vehicles, light trucks, and multipurpose passenger vehicles. Designing hitches for these applications is a complex engineering task, as the structures must withstand high dynamic loads while maintaining structural integrity over decades of use.

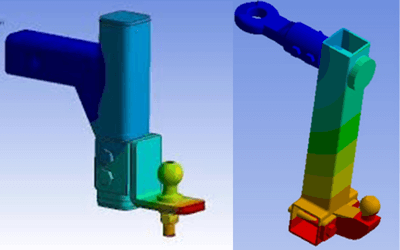

At Caliber Technologies, we begin our design process by creating high-fidelity 3D models of the hitch assembly, including couplings, mounting brackets, and safety chain connections. These models account for welds, fasteners, material non-linearities, and contact interactions, capturing the real-world behavior of the assembly. By simulating all critical load conditions defined in SAE J684 — including vertical tongue weight, lateral forces during turns, and towing forces during acceleration and braking — our engineers can accurately predict how the hitch will perform under extreme conditions.

Using FEA simulations, we perform detailed structural analysis to evaluate stress and strain distributions throughout the hitch assembly. This allows us to identify critical points where stress concentrations may occur, such as around mounting holes, cross-members, or weld joints. By understanding these vulnerable regions, our engineers can optimize the geometry, material selection, and reinforcement strategies to ensure the structure can safely carry the expected loads throughout its operational life.

Beyond basic strength analysis, we also perform buckling assessments to evaluate the stability of load-bearing members under compressive and bending forces. Buckling is a common failure mode in lightweight or tall hitch designs, and accurately predicting the onset of instability is crucial for safety and certification. Our simulations extend to fatigue and lifecycle analysis, enabling us to predict how the hitch will respond to repeated towing cycles over decades of service. By accounting for material fatigue and environmental factors, we ensure that the final design maintains structural integrity for more than 20 years, even under demanding towing conditions.

Caliber Technologies’ approach is highly iterative, combining FEA-driven insights with engineering expertise to continuously refine the design. We focus not only on compliance with SAE J684 but also on material efficiency, manufacturability, and weight optimization. By leveraging advanced simulation techniques, we reduce the need for physical prototypes, accelerating development timelines while maintaining the highest safety and quality standards.

Benefits of Caliber Technologies’ FEA Approach

- Regulatory Compliance: Full adherence to SAE J684, ensuring safety and certification readiness.

- Accurate Load Prediction: High-fidelity simulations capture real-world load distributions, including complex dynamic effects.

- Critical Point Identification: Structural weak points are identified early, allowing proactive reinforcement.

- Durability Assurance: Fatigue and lifecycle analysis confirm performance under repeated towing cycles.

- Optimized Material Usage: Strength is maximized while minimizing weight and cost, improving efficiency.

In conclusion, designing trailer hitches that meet rigorous safety standards requires a combination of advanced FEA simulations, detailed load analysis, and engineering expertise. Caliber Technologies provides end-to-end solutions for hitch design, delivering structures that are robust, durable, and fully compliant with SAE J684 standards. Through our simulation-driven approach, clients benefit from optimized designs, reduced development time, and enhanced confidence in the long-term performance of their towing systems.