Introduction

The alloy wheel is one of the most structurally and dynamically critical components of an automobile. Beyond its aesthetic appeal, the wheel directly influences vehicle safety, ride comfort, handling stability, and NVH (Noise, Vibration, and Harshness) performance. Due to the combination of static and dynamic loads transmitted through the suspension system, the wheel must withstand a complex spectrum of stresses while maintaining minimal weight.

Caliber Technologies LLC has developed a comprehensive simulation framework to assess alloy wheel performance under various real-world operating conditions using advanced Finite Element Analysis (FEA) tools such as ANSYS, Abaqus, HyperWorks, and Nastran. The framework integrates structural, fatigue, modal, and ride dynamics analyses to ensure a holistic evaluation of wheel integrity, durability, and NVH compliance.

Methodology Overview

The structural evaluation of the alloy wheel was executed using an FEA-based virtual validation approach. The process flow involves the following key stages:

- CAD Geometry Preparation and Meshing

- High-fidelity CAD geometry of the wheel is imported and cleaned to remove small fillets and non-structural features.

- The wheel model is discretized using tetrahedral or hexahedral elements, ensuring mesh convergence in high-stress zones such as the spoke–hub junction and rim–flange interface.

- Typical element size refinement is carried out in the bolt circle area, bead seat, and lug hole regions to accurately capture stress gradients.

- Material Properties

- The wheel is modeled using Aluminium Alloy (A356-T6 or AA6061) with nonlinear, strain-rate-dependent properties to reflect realistic response under impact conditions.

- The material model incorporates elastic-plastic behavior and fatigue parameters obtained from laboratory coupon testing or OEM database.

- Boundary Conditions and Loading

- Fixed support constraints are applied on the pitch circle diameter (PCD) holes, simulating wheel attachment to the hub assembly.

- Various loading conditions are defined to represent both static and dynamic service events, including:

- Radial Load Case: Simulating vehicle curb load or stationary vertical load.

- Curb Impact Load Case: Representing low-cycle fatigue events caused by sudden contact with road obstacles.

- Pothole Impact Load Case: Representing dynamic deformation during transient impact events.

- High-Cycle Fatigue Load Case: Derived from vehicle GVWR, wheel load distribution, and proving ground historical fatigue data.

- Solver Execution

- Nonlinear static and dynamic solvers are utilized to capture material yielding, contact nonlinearities, and geometric nonlinearity during high-load impact events.

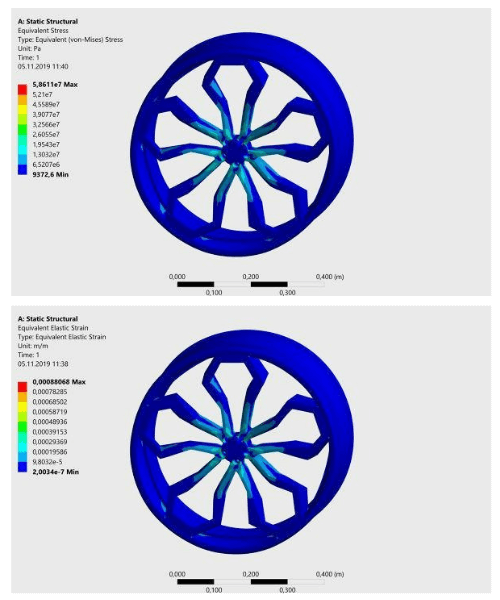

- Post-processing involves extraction of von Mises equivalent stress, total deformation, strain energy density, and contact pressure distributions.

Results and Discussion

3.1 Static Structural Analysis

Under the maximum design load corresponding to the vehicle GVWR, the maximum equivalent (von Mises) stress was observed at the spoke-root region, a typical failure-prone location in aluminum wheels.

- The stress levels were compared against the material yield strength to ensure sufficient safety margin.

- The maximum deformation was found at the rim flange, confirming acceptable compliance within design limits.

3.2 Modal and Dynamic Stiffness Analysis

To ensure proper NVH behavior, normal mode (modal) analysis was performed.

- The first natural frequency (wheel hop frequency) was compared against primary ride and tire cavity frequencies to avoid modal coupling.

- The static and dynamic stiffness values were extracted to quantify the wheel’s influence on unsprung mass NVH response.

- Modal separation was verified to prevent resonance with the suspension and chassis frequencies.

3.3 Fatigue and Durability Evaluation

- Low-cycle fatigue analysis was performed for curb and pothole impacts using strain-life (ε–N) approach to predict the initiation of cracks.

- High-cycle fatigue evaluation was based on cumulative damage (Palmgren–Miner rule) for repeated cyclic loading under road excitation.

- Results were validated against proving ground durability data and OEM benchmark standards such as SAE J328 / J2530.

Impact on Vehicle Performance

The design and optimization of wheel structure have direct implications on unsprung mass, vehicle ride dynamics, and handling characteristics.

- Reduction in unsprung mass improves primary ride comfort and suspension responsiveness.

- Optimized wheel stiffness enhances steering feel and cornering stability.

- NVH refinement is achieved by tuning modal frequencies and minimizing structural damping losses.

Caliber Technologies integrates multibody dynamics (MBD) and finite element co-simulation to evaluate how wheel design modifications influence vehicle-level responses, including ride comfort, wheel hop frequency, and road input transmissibility.

Conclusion

Caliber Technologies employs a multi-disciplinary simulation approach for alloy wheel development, encompassing:

- Structural integrity through static and dynamic FEA

- Durability and fatigue life prediction under real-world load histories

- Modal and NVH characterization for acoustic and vibration optimization

- Weight and stiffness optimization for enhanced vehicle dynamics

This comprehensive methodology ensures that the wheel design not only meets safety and durability requirements, but also contributes positively to ride comfort, NVH refinement, and performance efficiency of modern passenger vehicles. Caliber Technologies LLC (www.thecalibertech.com) is a Detroit-based engineering services company specializing in CAE-driven design, simulation, and validation for automotive systems. With expertise spanning structural FEA, CFD, Multibody Dynamics, and Mechatronic Systems, Caliber acts as an extension of your engineering teams, accelerating product development cycles while ensuring robustness, safety, and performance.