In both the RV and trucking industries, it is common practice to replace OEM-installed fifth-wheel hitches with aftermarket alternatives. These changes are typically driven by payload requirements, coupling preferences, wear replacement, availability, or compatibility with different tractor configurations. While aftermarket fifth-wheel manufacturers rigorously design their products to meet applicable standards and regulations, an important engineering question often remains unanswered:

What is the structural impact of a fifth-wheel hitch change on the trailer frame itself?

This question becomes especially critical for trailers employing upper-deck frame architectures, where hitch loads are transmitted through complex load paths into the primary structure.

1) Engineering Complexity of Fifth-Wheel Hitch Design

A fifth-wheel hitch is not a passive interface component. It is a primary structural load input into the trailer system, responsible for transmitting:

- Vertical static loads from kingpin weight

- Dynamic vertical road excitation

- Longitudinal braking and traction forces

- Lateral cornering forces

- Torsional loads from uneven terrain and articulation

Small changes in hitch geometry, stiffness, mounting footprint, or load transfer characteristics can significantly alter how these forces are introduced into the trailer frame.

2) Existing Standards and Regulatory Coverage

There are well-established international and domestic standards governing fifth-wheel hitch design, interchangeability, and performance:

| Standard / Regulation | Type | Scope |

| ISO 3842 | Design / Dimensional | Interchangeability of fifth-wheel interfaces internationally |

| ISO 4086 | Dimensional | Kingpin size and fit for heavy vehicles |

| SAE J2638 | Performance | Static and dynamic strength and durability testing of fifth-wheel hitches |

| 49 CFR § 393.70 | U.S. Federal Regulation | Safety requirements for coupling devices and mounting |

| Fastener Guidelines | Industry Practice | Recommended bolt counts and fastening practices |

Collectively, these standards ensure that:

- The hitch can safely couple and decouple

- Interchangeability is maintained

- The hitch itself meets strength and durability requirements

- Installation meets minimum safety expectations

However, none of these standards explicitly require an evaluation of the downstream structural effects on the trailer frame when a hitch is replaced.

3) The Structural Gap in Current Industry Practice

Current regulations and standards primarily focus on:

- Hitch operability

- Interface geometry

- Hitch structural integrity

- Safety compliance of the coupling device

What is typically not addressed is:

- Changes in frame load distribution due to different hitch stiffness

- Local stress redistribution in upper-deck frames

- Increased torsional compliance or stiffness mismatch

- Long-term fatigue implications at frame rails, crossmembers, and weld joints

- Interaction between hitch mounting strategy and trailer flexibility requirements

This gap is particularly concerning for trailers with upper-deck frame designs, where:

- Hitch loads are introduced above the neutral axis

- Load paths are longer and more complex

- Frame flexibility is intentionally designed to manage torsion and articulation

- Over-constraining the structure can accelerate fatigue damage

4) Why Upper-Deck Trailer Frames Are Especially Sensitive

Upper-deck trailer architectures rely on a delicate balance between:

- Global frame stiffness

- Local compliance at the hitch interface

- Controlled torsional flexibility to accommodate road-induced twist

Aftermarket fifth-wheel hitches may differ from OEM designs in:

- Base plate thickness

- Mounting footprint size

- Fastener pattern density

- Vertical and torsional stiffness

- Load introduction height and contact area

Even when fully compliant with ISO, SAE, and CFR requirements, these differences can unintentionally:

- Increase local bending stresses

- Shift fatigue damage locations

- Restrict intended frame twist

- Create new stress concentrations at weld toes and attachments

These effects often manifest not as immediate failures, but as long-term durability issues—cracking, loosening, or deformation after extended service.

5) Caliber Technologies’ Engineering Assessment Approach

Recognizing this industry gap, Caliber Technologies has developed a structural assessment methodology to evaluate fifth-wheel hitch replacement impacts on trailer frames—without implying certification or regulatory validation.

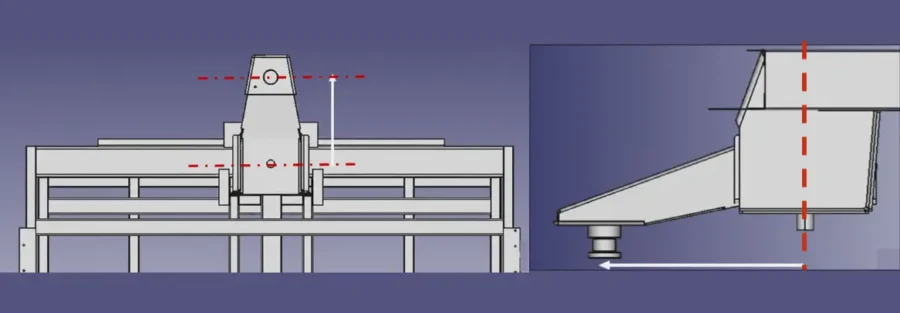

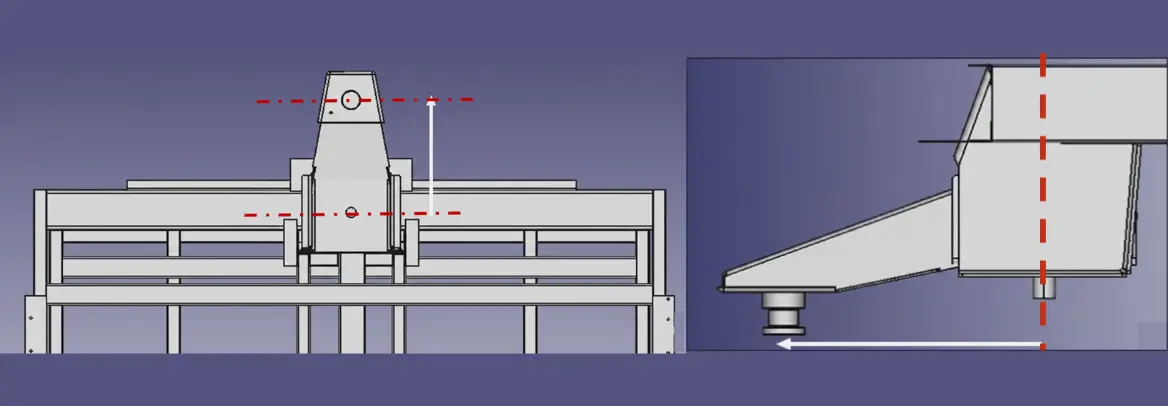

a) Digital Structural Modeling

A detailed finite element model of the upper-deck trailer structure was developed, including:

- Frame rails and crossmembers

- Upper-deck structure

- Hitch mounting interfaces

- Local reinforcements and fasteners

Two different fifth-wheel hitch designs were integrated into the model, each compliant with applicable standards.

b) Load Case Development

Caliber Technologies applied proprietary load cases representing static kingpin loads, equivalent dynamic vertical road excitation, longitudinal braking and traction, lateral cornering, torsional twist from uneven terrain. These load cases were developed to represent realistic operating environments, not just static certification scenarios.

c) Comparative Structural Assessment

The analysis evaluated:

- Stress distribution in frame rails and crossmembers

- Hitch-induced torsional stiffness changes

- Localized fatigue-sensitive regions

- Load path changes between hitch designs

- Relative flexibility of the upper-deck structure

The results clearly demonstrated that:

- Two compliant hitch designs can produce materially different structural responses

- Hitch mounting stiffness and footprint significantly influence frame durability

- Overly stiff or over-constrained hitch mounting can negatively affect long-term fatigue performance

6) Engineering Guidelines for Hitch Replacement

Based on this work, Caliber Technologies developed engineering guidelines to help customers and aftermarket manufacturers. These guidelines provide a structurally informed pathway for hitch replacement—bridging the gap between hitch-centric standards and trailer frame durability considerations.

Closing Thoughts

The industry has done an excellent job standardizing fifth-wheel hitch design, interchangeability, and safety. However, compliance alone does not guarantee system-level structural robustness, especially for complex trailer architectures. As trailers continue to evolve with higher payloads, custom upper-deck structures, and longer service expectations, it becomes increasingly important to treat fifth-wheel hitch replacement as a system-level structural decision, not just a component swap. Digital structural engineering assessments provide the insight needed to make these decisions responsibly—protecting frame durability, operational safety, and long-term reliability without impeding innovation.