Introduction and Background

The frame is the structural backbone of any recreational vehicle (RV) or travel trailer—it carries the vehicle’s weight, supports the body, and transfers loads from the suspension to the superstructure. Despite this central role, the RV industry has traditionally relied heavily on frame suppliers to provide “standard” or “off-the-shelf” chassis systems. These frames are often developed to satisfy a broad range of applications, leading to compromises in stiffness, weight distribution, and fatigue life when adapted to a specific RV model.

While supplier-provided frames may meet baseline Gross Vehicle Weight Rating (GVWR) requirements, this metric alone is far too simplistic to ensure long-term performance. GVWR defines the maximum total load that a trailer can safely carry, but it does not account for how that load is distributed, where it is applied, or how the frame interacts dynamically with the body and suspension.

In reality, RV frames experience complex and variable loading conditions, including:

- Uneven road inputs leading to torsional twisting of the chassis.

- Concentrated loads at localized floor or wall attachment points.

- Dynamic forces during braking, cornering, or hitch articulation.

- Superstructure stiffness interactions—where the walls, floor, and roof either support or amplify frame deformation.

As a result, using GVWR alone as a frame selection criterion often leads to underperforming structural systems that suffer from:

- Excessive frame flex or sag over time.

- Fatigue cracking near high-stress regions (such as the A-frame, suspension hangers, or crossmember joints).

- Wall and roof separation due to excessive vertical and torsional deflection.

- Noise, Vibration, and Harshness (NVH) issues, leading to squeaks, rattles, and customer dissatisfaction.

Mitigating these failures requires more than generic frames—it demands tailored frame architecture engineered for the specific RV layout, usage profile, and structural integration. This is where Caliber Technologies brings unmatched capability to the RV industry.

The Industry’s Reliance on Supplier-Provided Frames

Most RV OEMs depend on their frame suppliers for chassis design, leveraging supplier expertise and manufacturing infrastructure. While this model is practical for cost and logistics, it also means that OEMs often accept standardized designs optimized for the “average” use case rather than their unique vehicle architecture.

Figure: Example of the RV with upper deck and 5th wheel

Supplier frames are typically designed with conservative factors of safety and broad flexibility, allowing them to serve multiple customers with minimal modification. However, such designs often fail to account for:

- The unique floor layout and internal load paths of each RV model.

- Torsional coupling between frame and superstructure.

- Vertical load asymmetry due to equipment placement (water tanks, appliances, batteries, etc.).

- The effects of tongue weight and hitch geometry on front frame deflection.

Consequently, manufacturers must frequently modify these base frames—adding crossmembers, gussets, stiffeners, or load spreaders—to achieve desired stiffness and fatigue performance. Without advanced simulation or analytical support, these modifications are often reactive and empirical, leading to extended development cycles, additional cost, and inconsistent product quality.

The industry’s dependence on supplier frames thus constrains innovation and performance optimization. A more proactive, OEM-led engineering approach—supported by digital simulation and structural optimization—is necessary to develop frames that meet specific product performance and durability goals.

Caliber Technologies’ Expertise in RV Frame Design

Caliber Technologies (www.thecalibertech.com) has extensive experience in helping RV manufacturers select, design, and optimize frame systems that are perfectly aligned with their product requirements. Our approach blends engineering fundamentals, digital simulation, and collaborative supplier integration to ensure each frame meets the right balance of strength, stiffness, weight, and cost.

We have successfully partnered with multiple OEMs and suppliers to:

- Define architecture-specific frame layouts for both single- and multi-axle towables.

- Assess and redesign load-bearing members to eliminate localized fatigue issues.

- Optimize crossmember spacing for stiffness and weight balance.

- Integrate floor and wall structures into the load path for better overall durability.

- Establish simulation-based design standards that replace trial-and-error testing.

Our engineering process focuses on the complete vehicle system—not just the bare frame. By understanding how loads travel from the road, through the suspension, into the frame, and finally into the superstructure, we can make targeted design improvements that enhance both performance and longevity.

Caliber’s Digital Engineering Approach

Caliber Technologies employs state-of-the-art Finite Element Analysis (FEA) and digital modeling to predict and optimize how RV frames behave under real-world operating conditions. This data-driven approach allows our engineers to evaluate multiple design configurations before any physical prototype is built.

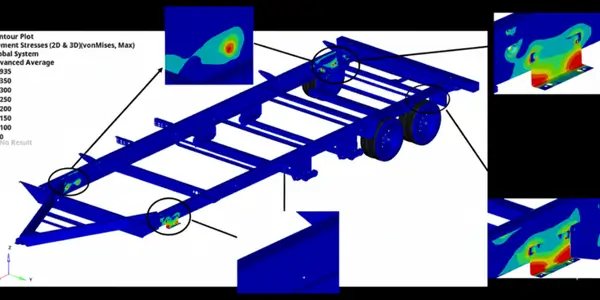

Finite Element Analysis (FEA) for Structural Optimization

FEA enables precise modeling of (i) Static bending and torsion stiffness to control deflection under load. (ii) Dynamic load cases, such as road inputs, braking forces, and hitch articulation. (iii) Local stress concentrations at welds, holes, and attachment points. (iv) Fatigue life prediction based on realistic duty cycles and road spectra.

We use FEA to optimize frame geometry, member sizing, and material selection, ensuring sufficient stiffness without excessive weight. This approach also helps identify failure-prone regions before production, allowing for structural reinforcements or design changes early in development.

System-Level Modeling

Beyond the frame itself, Caliber integrates the superstructure (walls, floor, roof) into the digital model to evaluate how each subsystem contributes to overall rigidity. This “frame + body” modeling technique provides a more realistic understanding of: How the superstructure supports (or amplifies) frame flex. How load-sharing can be improved through better joint design or materials. How NVH characteristics evolve across the assembled RV.

Load Case Development

Generic GVWR-based load assessments fail to represent real-world usage. Caliber Technologies has developed a comprehensive set of custom load cases, including:

- Road-induced vertical and torsional loads from potholes, bumps, and uneven surfaces.

- Dynamic hitch loads due to acceleration, braking, and cornering.

- Overload conditions representing real customer usage beyond manufacturer recommendations.

- Static park loads representing long-term loading at rest.

These analyses ensure the frame can withstand peak short-term loads and long-term fatigue cycles without deformation or crack propagation.

NVH and Ride Performance

Frame stiffness also affects the noise and vibration behavior of the RV. Excessive flex can lead to squeaks, rattles, and resonance issues. Caliber Technologies applies modal and harmonic analysis to study frame vibration modes and transfer paths. This enables targeted improvements to reduce interior noise and enhance ride comfort.

Collaborative Frame Redesign with Suppliers

Caliber Technologies’ role does not replace the supplier—it empowers both OEMs and suppliers to collaborate more effectively. Once the optimal frame architecture is defined through simulation, we work with suppliers to:

- Incorporate manufacturability constraints into the final design.

- Validate joint and weld details through fatigue analysis.

- Define material thicknesses, cross sections, and reinforcements tailored to the specific trailer geometry.

- Develop design documentation and validation plans that align with OEM targets and supplier capabilities.

This collaborative model bridges the gap between OEM performance requirements and supplier manufacturing expertise, ensuring a robust and cost-efficient solution.

The Benefits of Caliber’s Approach

- By leveraging Caliber Technologies’ advanced simulation and system integration expertise, RV manufacturers gain a series of tangible benefits:

- Improved Frame Durability: Reduced cracking and fatigue failures through optimized stress distribution.

- Enhanced Ride and NVH Performance: Better stiffness and vibration control lead to quieter, smoother operation.

- Weight Optimization: Stronger yet lighter designs, improving towing efficiency and payload capacity.

- Reduced Warranty Costs: Fewer structural issues and longer component life.

- Faster Development Cycles: Digital validation eliminates multiple prototype iterations.

- Product Differentiation: OEMs can define unique performance characteristics that align with their brand positioning.

Conclusion

The RV frame is not just a supporting structure—it’s the foundation of performance, durability, and customer satisfaction. Relying solely on supplier-provided generic designs limits the potential of what a trailer can achieve.

Caliber Technologies (www.thecalibertech.com) empowers RV manufacturers to take control of their frame architecture through advanced digital engineering, finite element modeling, and structural optimization. Our approach ensures that each frame is engineered to match the specific load paths, geometry, and usage profile of the RV, delivering the perfect balance of strength, stiffness, and ride quality.

By combining deep automotive structural expertise with modern simulation tools, Caliber Technologies helps OEMs design frames that not only meet regulatory standards but also exceed customer expectations—lasting longer, performing better, and contributing to a quieter, more refined RV experience.