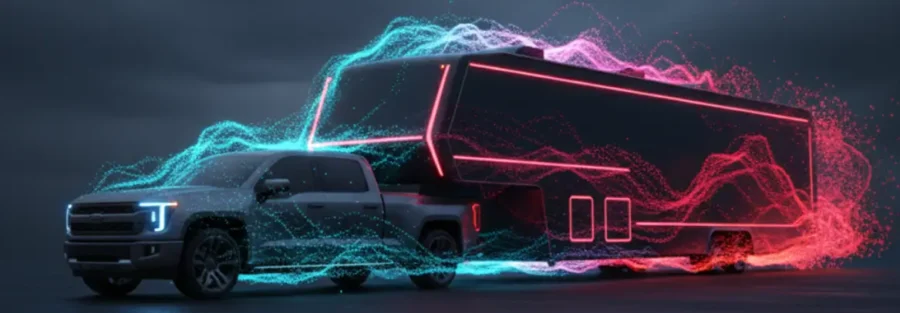

Introduction: The Untapped Opportunity in RV Aerodynamics

The recreational vehicle (RV) industry has long prioritized comfort, space utilization, and manufacturing efficiency—but aerodynamic optimization has remained largely overlooked. As a result, even modern towable RVs continue to exhibit high aerodynamic drag, leading to poor fuel economy, reduced range, and suboptimal towing performance.

When towed behind heavy-duty trucks such as the Ford F-150, F-250, or F-350, a travel trailer can dramatically alter the combined vehicle’s aerodynamic characteristics. The bluff body shape of most RVs produces significant flow separation zones, high-pressure drag at the front, and strong suction zones at the rear, all of which contribute to energy losses. For the tow vehicle, this means increased fuel consumption and reduced stability, especially at highway speeds.

As the industry moves toward electrification, the need for aerodynamic efficiency becomes even more critical. The adoption of electric tow vehicles and the emergence of EV-based RVs highlight the necessity for designs that minimize drag and maximize range. Reducing aerodynamic drag by even small margins can yield measurable gains in miles per gallon (MPG) for internal combustion engine (ICE) tow vehicles and extended driving range for electric vehicles.

This is where Caliber Technologies—a leader in digital engineering and simulation—plays a transformative role. By applying Computational Fluid Dynamics (CFD) analysis and design optimization, Caliber Technologies enables RV manufacturers to visualize, quantify, and improve how air flows around both the tow vehicle and trailer combination, translating simulation results into real-world efficiency gains.

Caliber Technologies’ CFD-Based Digital Engineering Approach

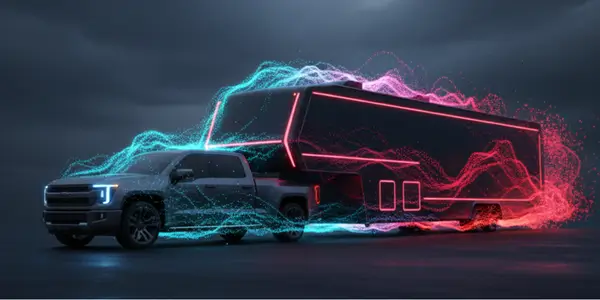

Caliber Technologies leverages CFD simulation to model and optimize the aerodynamic performance of RVs and their corresponding tow vehicles. This digital approach provides a deep understanding of how airflow, pressure distribution, and drag forces interact across the entire vehicle combination.

Full-System Modeling: Truck + RV Integration

Unlike traditional CFD analyses that focus solely on the trailer, Caliber Technologies models the entire system—the tow vehicle (e.g., Ford F-150/250/350) coupled with the RV. This approach recognizes that the aerodynamic behavior of a trailer cannot be isolated; it is strongly influenced by the wake, turbulence, and pressure zones created by the tow vehicle.

By simulating the complete truck-trailer configuration, engineers can:

- Identify interference drag zones caused by the gap between the truck cab and trailer nose.

- Optimize the front radius and curvature of the trailer to reduce wake turbulence and pressure drag.

- Examine side wind effects to ensure vehicle stability in crosswind conditions.

- Assess flow separation and vortex shedding patterns behind the trailer to minimize rear suction.

These simulations are performed under realistic highway-speed conditions (e.g., 55–75 mph) and consider multiple yaw angles to replicate real-world driving.

Aerodynamic Optimization through Design Iteration

Using parametric modeling and CFD-based optimization, Caliber Technologies iterates through multiple design concepts to evaluate their impact on aerodynamic performance. Each iteration provides detailed insights into:

- Coefficient of drag (Cd) and lift (Cl)

- Pressure distribution maps along the front, sides, and rear

- Flow visualization through streamlines and vorticity plots

- Turbulence intensity and wake structure behavior

By comparing these results, engineers can pinpoint which geometric changes yield the most significant improvements. Typical modifications include:

- Adjusting front-end curvature and leading-edge radius

- Optimizing roof slope and transition surfaces between the truck and RV

- Integrating fairings or vortex generators at critical flow separation points

- Redesigning rear-end taper angles to reduce base pressure drag

CFD Beyond Drag: Stability and Comfort

While drag reduction is the primary goal, Caliber’s CFD approach also considers stability and ride comfort. For example, changes that reduce drag must not compromise side-force balance or yaw stability during crosswinds. Caliber Technologies uses CFD to evaluate how side gusts and buffeting affect the combined vehicle system, ensuring that aerodynamic gains also enhance handling and towing stability.

Translating CFD Results into Real-World Efficiency

A key differentiator of Caliber Technologies is its ability to bridge the gap between simulation and real-world vehicle performance. CFD results are not just presented as abstract data; instead, they are translated into meaningful metrics that resonate with both manufacturers and consumers.

From Coefficient of Drag to Fuel Efficiency

The coefficient of drag (Cd) quantifies how aerodynamic resistance affects vehicle motion. A reduction in Cd directly correlates to improved efficiency. For instance:

- A 10% reduction in aerodynamic drag can yield 3–5% improvement in fuel economy for typical highway towing conditions.

- For an ICE-powered tow vehicle such as a Ford F-250, this can translate into 0.5–1.0 additional miles per gallon (MPG), depending on speed and payload.

Caliber Technologies uses CFD-derived drag forces to calculate aerodynamic power losses, which are then converted into energy consumption estimates for both ICE and EV applications.

Translating Aerodynamics into EV Range

For electric vehicles, every watt of energy saved contributes to increased driving range. By quantifying drag-related energy losses, Caliber Technologies can estimate how improved aerodynamics extend the range of EV tow vehicles or electric RVs.

For example:

- A 5% drag reduction could increase an EV tow vehicle’s range by 3–4%, depending on speed and battery capacity.

- For electric RVs designed with integrated propulsion, aerodynamic refinement can improve range by 10–15 miles per charge.

This direct translation from CFD-derived drag coefficients to consumer-relevant metrics—miles per gallon or miles per charge—allows RV manufacturers to market tangible performance benefits that align with growing consumer interest in sustainability and efficiency.

Aesthetic and Functional Integration

Caliber Technologies’ CFD-driven design optimization also supports aesthetic improvement. Aerodynamic enhancements often result in smoother, more cohesive designs that align with modern automotive styling. By integrating form and function, manufacturers can produce RVs that are not only efficient but also visually appealing—helping brands stand out in a crowded marketplace.

The Importance of Aerodynamics in the Future of RV Design

The transition toward electric mobility has accelerated the need for aerodynamic optimization. While large tow vehicles powered by ICE engines can compensate for aerodynamic inefficiencies through power, EVs are far more sensitive to drag losses. Poor aerodynamics directly diminish range, which is one of the key purchasing considerations for EV consumers.

The RV industry’s historical focus on interior space and manufacturing simplicity has left considerable efficiency potential untapped. By adopting CFD-based digital design processes, manufacturers can:

- Improve fuel efficiency and range

- Enhance vehicle stability and towing comfort

- Reduce noise and buffeting from airflow

- Deliver aesthetically refined and energy-efficient designs

Caliber Technologies’ multi-disciplinary expertise in both automotive and aerospace-grade simulation enables RV manufacturers to bridge this performance gap effectively. The firm’s end-to-end capabilities—from aerodynamic modeling to design refinement and performance translation—offer a comprehensive pathway to next-generation, high-efficiency RVs.

Conclusion

Caliber Technologies brings advanced CFD-based aerodynamic optimization to the RV industry, addressing one of its most underdeveloped areas—vehicle efficiency. By modeling the complete truck and trailer system, Caliber enables manufacturers to understand airflow interactions, reduce aerodynamic drag, and translate those improvements into real-world performance gains.

This capability is more than just simulation—it is a bridge between engineering precision and customer value. By quantifying how aerodynamic improvements translate into better fuel economy, longer EV range, and enhanced stability, Caliber Technologies empowers manufacturers to design RVs that are both beautiful and efficient.

As the RV industry evolves toward sustainability and electrification, aerodynamic design optimization will become a defining competitive advantage. Caliber Technologies stands at the forefront of this transformation—helping manufacturers engineer the future of efficient, innovative, and high-performance RVs through the power of digital engineering and CFD simulation.