Modern vehicle development demands a delicate balance between handling precision, ride comfort, and steering feel. Suspension systems are at the core of this balance, dictating how forces are transmitted from the road to the vehicle body and steering system. Among these, the front suspension compliance characteristics play a crucial role in defining the vehicle’s understeer gradient, steering stability, and overall handling behavior.

At Caliber Technologies LLC, we specialize in combining Multi-Body Dynamics (MBD) and optimization-based simulation techniques to fine-tune suspension systems for performance and comfort targets. This case study presents our approach to multi-objective optimization of front suspension compliance to increase vehicle understeer, while maintaining critical performance metrics such as brake stiffness, torque steer, and ride quality.

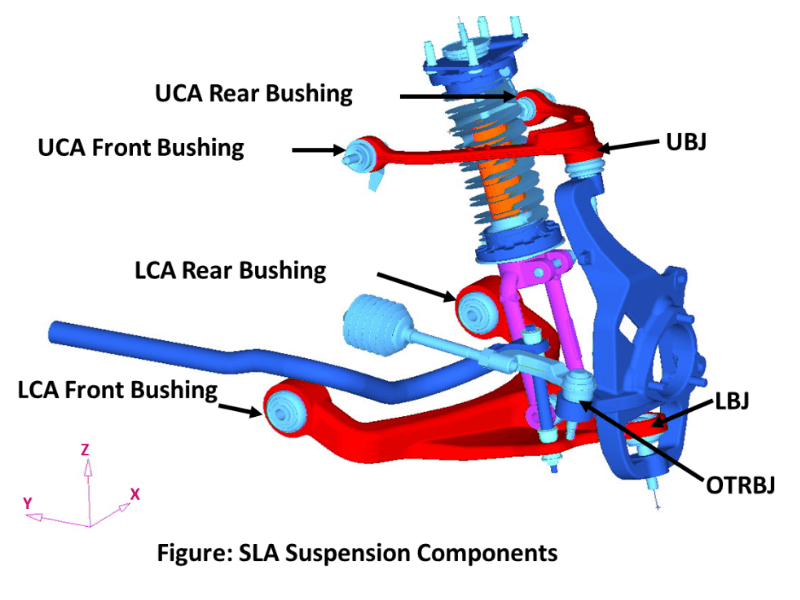

Suspension type: Double wishbone suspension.

A double wishbone suspension utilizes two wishbone-shaped control arms (upper and lower), each with two chassis mounting points and a single joint at the knuckle, allowing for truly independent wheel movement and precise tuning of suspension geometry. Engineers can optimize parameters such as camber gain, roll center height, and toe patterns, making this system highly effective for performance and handling.

Bushing tuning options with double wishbone setups are extensive: the bushings at the arm-to-chassis connections can be varied in material (rubber, polyurethane, hydro) and stiffness profile to filter road noise, manage compliance, and balance comfort versus crisp handling response. Stiffer bushings sharpen steering and minimize unwanted deflection, while softer or hydraulic bushings enhance ride isolation and NVH. By selecting bushing properties for both upper and lower arms, engineers can tune for understeer/oversteer, optimize kinematics, and even tailor compliance in load paths for performance or luxury characteristics.

Project Overview

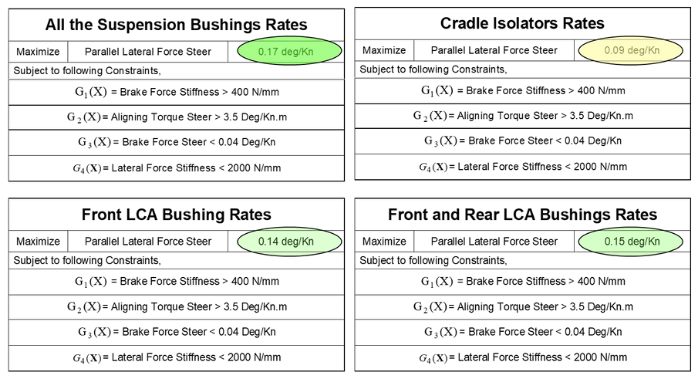

The objective of this study was to induce more compliance from the front suspension in order to increase overall vehicle understeer. The baseline vehicle configuration exhibited a parallel lateral force steer (PLFS) value of 0.07°/kN under lateral force application — a condition correlating to a relatively neutral steering behavior.

To improve vehicle stability and cornering predictability, the goal was to increase PLFS, thereby enhancing understeer characteristics. However, this optimization had to be achieved through minimal and tunable changes — primarily via bushing stiffness modifications — to ensure no significant impact on vehicle timing, packaging, or production cost.

Simulation Framework and Methodology

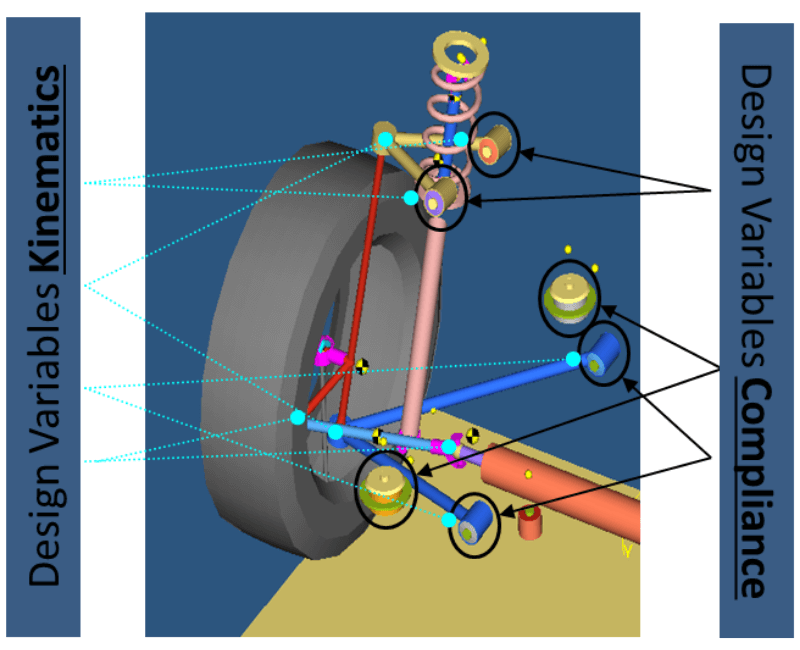

1) Multi-Body Dynamics Model Setup

A full-vehicle multi-body dynamics (MBD) model was developed using ADAMS/Car, incorporating realistic representations of the front and rear suspension subsystems, steering system, and tire models. Each control arm, bushing, and subframe mount was modeled with appropriate stiffness and damping properties to accurately capture compliance behavior under multiple load cases.

This simulation framework enabled Caliber Technologies engineers to perform a detailed Kinematics and Compliance (K&C) analysis, isolating the influence of each suspension component on lateral force steer, brake force steer, and aligning moment torque steer.

2) Sensitivity Analysis and Key Design Variables

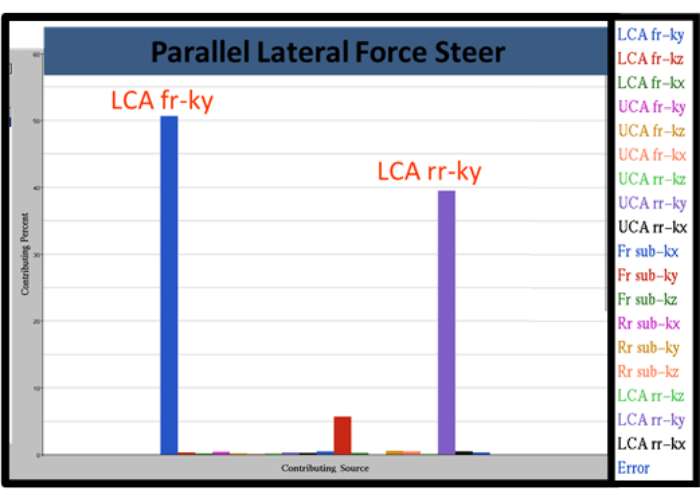

To identify the most influential parameters affecting the parallel lateral force steer (PLFS), a Design of Experiments (DOE) and sensitivity analysis were conducted. The key design variables considered in this study included:

- Lower Control Arm (LCA) bushings – front and rear positions, rates in X, Y, Z directions

- Upper Control Arm (UCA) bushings – front and rear positions, rates in X, Y, Z directions

- Subframe bushings – front and rear positions, rates in X, Y, Z directions

Each of these bushings affects the suspension’s compliance under combined lateral, longitudinal, and braking loads. The sensitivity analysis quantified the correlation between each bushing stiffness and the resulting steering/handling metrics.

This systematic evaluation allowed engineers to determine which stiffness parameters contributed most significantly to PLFS, while understanding trade-offs with other performance attributes.

3) Multi-Objective Optimization Setup

Once sensitivity relationships were established, a multi-objective optimization routine was performed using an integrated MBD and optimization solver framework. The objectives and constraints were defined as follows:

Optimization Objectives:

Increase parallel lateral force steer (PLFS) beyond the baseline value of 0.07°/kN to induce higher understeer.

Performance Constraints:

| Sr. | Constraints | Vehicle level impact |

| 1 | Brake Force Stiffness ≥ 400 N/mm | To maintain proper pedal feel and prevent excessive suspension deflection during braking. |

| 2 | Aligning Moment Torque Steer ≥ 3.5°/kN | To ensure that self-aligning torque does not reduce overall understeer. |

| 3 | Brake Force Steer ≤ 0.04°/kN | To prevent undesirable toe or steering input during braking events. |

| 4 | Lateral Force Stiffness ≤ 2000 N/mm | To avoid excessive suspension harshness or reduced compliance over rough surfaces. |

This combination of performance objectives and constraints ensures that the optimized suspension preserves vehicle comfort and safety while achieving the desired handling improvement.

4) Results and Observations

The optimization revealed that tuning of the lower control arm rear bushing and front subframe bushing stiffness had the most significant influence on parallel lateral force steer (PLFS).

By softening the LCA rear bushing in lateral direction and slightly increasing lateral stiffness for front LCA bushing stiffness in lateral direction, engineers were able to increase PLFS by approximately 100%, translating into a noticeable increase in vehicle understeer.

The optimized configuration maintained a brake stiffness of 412 N/mm, ensuring braking feel remained within target limits. Brake force steer was contained below 0.04°/kN, confirming that steering behavior remained stable during braking events. Aligning moment torque steer was preserved above 3.5°/kN, preventing unwanted steering torque losses.The overall lateral force stiffness was kept below 2000 N/mm, maintaining ride comfort and compliance over rough terrain.

This multi-objective optimization demonstrated that minor, tunable changes in bushing stiffness could significantly improve handling balance without impacting vehicle cost, weight, or packaging. This also reduced the whole tuning exercise and prototype part ordering to minimum saving significant time and cost while providing upfront visibility on objectiveness that is often lacking in the field of vehicle dynamics.

5) Engineering Insights

The results highlight several key engineering insights:

- Front suspension compliance tuning is one of the most effective levers for refining vehicle understeer/oversteer balance.

- Bushing stiffness optimization targeted towards the lower control arm offers a low-cost and rapid solution for handling refinement during late-stage vehicle development.

- Combining MBD-based sensitivity analysis with multi-objective optimization provides a powerful framework for identifying trade-offs and achieving balanced dynamic performance.

- The integrated approach ensures that enhancements in one area (understeer improvement) do not degrade others (braking stability, ride comfort, or steering torque).

Conclusion

Through the combination of ADAMS/Car-based MBD simulation, DOE-driven sensitivity analysis, and multi-objective optimization, Caliber Technologies LLC successfully demonstrated the ability to enhance vehicle understeer characteristics through precise suspension compliance tuning.

This study underscores Caliber’s expertise in vehicle dynamics simulation, suspension optimization, and virtual validation, helping OEMs and Tier-1 suppliers achieve handling, comfort, and safety targets with minimal cost and design impact.

By leveraging simulation-led design optimization, Caliber Technologies enables its clients to develop better-balanced, dynamically refined vehicles that deliver superior real-world driving performance.