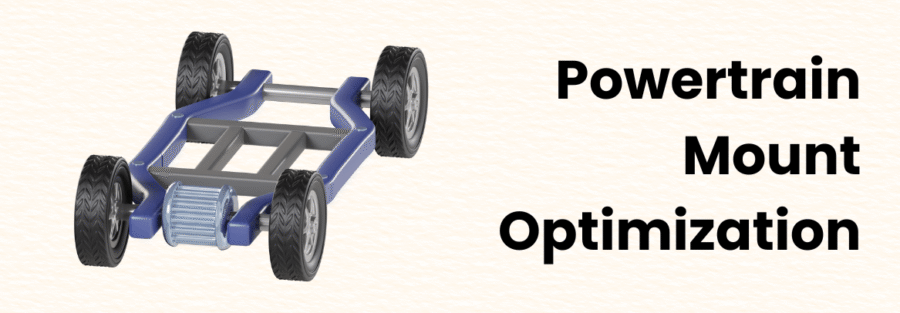

In modern vehicle design, optimizing the powertrain mounting system is critical to minimize vibrations transmitted to the chassis, ensure passenger comfort, and comply with stringent packaging constraints. Caliber Technologies specializes in sophisticated powertrain mount optimization leveraging state-of-the-art multi-body dynamics simulation platforms such as ADAMS, SIMPACK, and MotionView.

Challenge Overview

- Vibration Control: Powertrain induced vibrations significantly contribute to noise, vibration, and harshness (NVH) inside the vehicle cabin. Minimizing these vibrations through mount design reduces occupant discomfort and improves vehicle refinement.

- Packaging Constraints: Powertrain mounts must be designed within tight confines dictated by engine bay space, ancillary components, and chassis geometry, limiting layout flexibility.

Innovative Solution Approach

Caliber Technologies adopts a rigorous multi-disciplinary simulation methodology combining multi-body dynamics with advanced optimization algorithms to solve these challenges effectively:

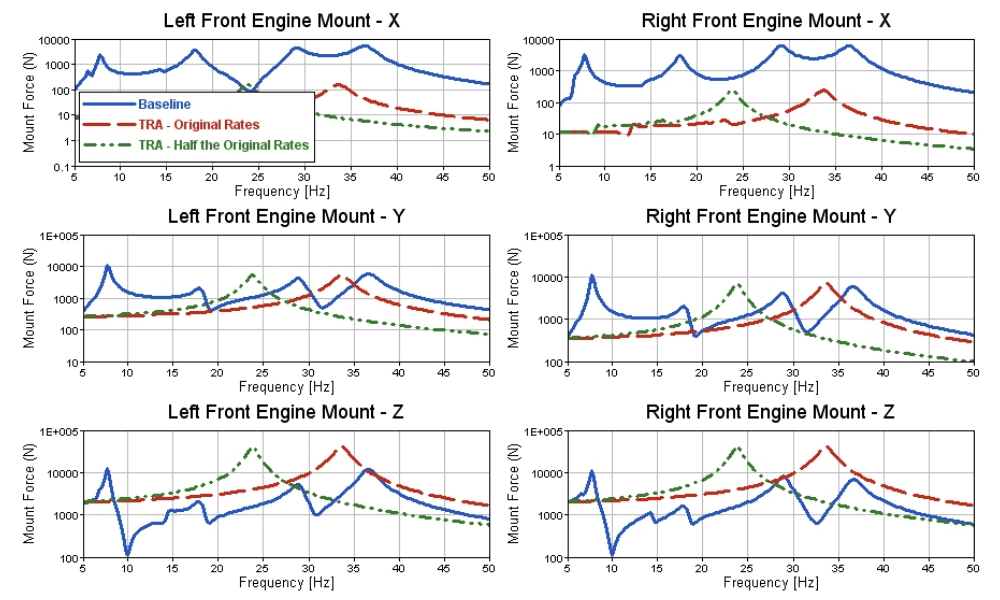

- Torque-Roll-Axis (TRA) Optimization: Our engineers run detailed TRA studies aimed at decoupling the roll mode—a dominant contributor to powertrain vibration transmission. Decoupling reduces the coupling between engine motion and chassis response.

- Genetic Algorithms for Design Optimization: A specially developed genetic algorithm-based routine automates multi-objective optimization, efficiently searching a high-dimensional design space. This routine optimally selects mount coordinates and mount stiffness/damping rates as design variables.

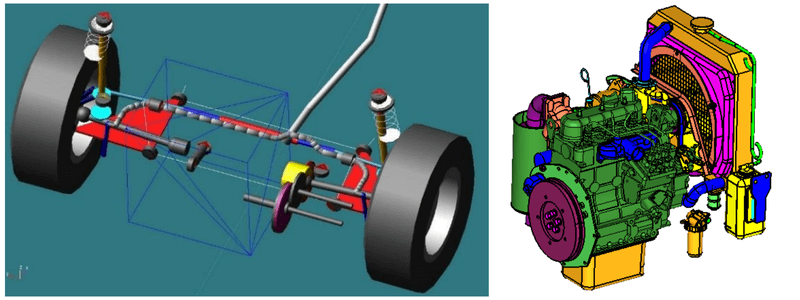

- Multi-Body Dynamics Platforms: We deploy ADAMS, SIMPACK, and MotionView simulations to capture the nonlinear dynamic interactions among powertrain, mounts, and chassis accurately. These platforms enable detailed modeling of mount stiffness characteristics, frictional effects, and load paths.

Benefits Realized from TRA Decoupling

The primary outcome of this approach is the successful decoupling of the torque-roll-axis mode that translates into:

- Drastic Reduction in High-Frequency Vibrations: Our optimized mounts nearly eliminate powertrain-induced high-frequency vibration transmission into the chassis, significantly enhancing NVH performance.

- Simplified System Dynamics: The complex multi-degree-of-freedom system governing powertrain-chassis interactions effectively reduces to a single primary degree-of-freedom, simplifying control and prediction.

- Scalable Mount Rates: Post-optimization, mount stiffness and damping rates become tunable parameters enabling precise placement of the roll mode frequency. This frequency can be strategically placed below the engine operating range, thus avoiding resonance during typical operation.

Caliber Technologies’ Expertise and Capabilities

Caliber Technologies combines deep engineering knowledge, rigorous physics-based modeling, and advanced computational tools to deliver:

- Accurate representation of mount non-linearities and frictional effects

- Coupled multi-body simulations capturing powertrain, mounts, and chassis dynamic interaction

- Custom optimization workflows integrating genetic algorithms with multi-body solvers

- Comprehensive design variable selection facilitating practical solutions respecting physical and packaging constraints

- Close collaboration to interpret simulation results towards actionable engineering modifications

Interested in how Caliber Technologies can optimize your vehicle’s powertrain mounting system using state-of-the-art multi-body dynamics and optimization? Our tailored solutions can drastically improve vehicle comfort, durability, and performance.