Introduction

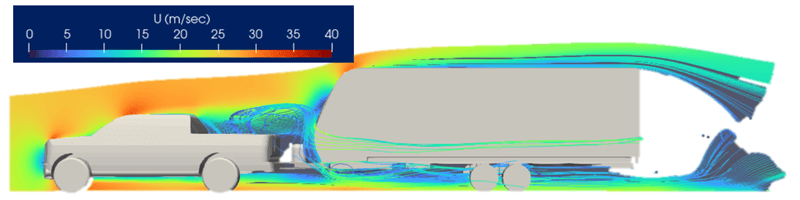

In modern vehicle and trailer design, aerodynamic drag is one of the most dominant factors influencing fuel efficiency, stability, and drivability—especially for pickup trucks towing large travel trailers. When a vehicle-trailer combination moves at highway speeds, the interaction between the truck wake and trailer frontal flow can generate significant aerodynamic resistance and unsteady flow patterns, leading to increased fuel consumption, higher yaw moments, and reduced vehicle stability.

The Recreational Vehicle (RV) industry has experienced significant growth over the past decade, driven by consumers’ increasing desire for mobility, comfort, and freedom during travel. As modern RVs and travel trailers become larger, more feature-rich, and aerodynamically complex, the need to optimize their performance from both structural and aerodynamic perspectives has never been greater. When an RV or trailer is towed at highway speeds, its shape, frontal area, and flow interaction with the towing vehicle collectively determine the aerodynamic drag, which directly impacts fuel efficiency, handling stability, and driver comfort.

In particular, towable RVs such as conventional hitch trailers and fifth-wheel trailers present unique aerodynamic challenges. A hitch trailer—commonly attached via a ball-type or weight-distribution hitch to the rear of a pickup truck or SUV—typically has a large front wall that sits directly in the turbulent wake of the tow vehicle. The resulting recirculation and low-pressure zones between the truck cab and trailer front face cause substantial pressure drag and flow separation, increasing the combined drag coefficient (CD) and overall fuel consumption. These effects are particularly pronounced when using full-size pickup trucks like the Ford F-250, where the trailer’s front face aligns closely with the truck’s wake region.

In contrast, a fifth-wheel trailer, which mounts onto a gooseneck-style hitch positioned above the rear axle of the tow vehicle, benefits from a smoother aerodynamic transition between the truck cab and trailer nose. The elevated coupling point and overhanging trailer front reduce the size of the separated wake region, improving airflow continuity and reducing the overall CD. However, this design introduces different flow complexities, such as increased roof-level turbulence and potential unsteady side vortices that influence vehicle yaw stability and crosswind sensitivity.

Both hitch-mounted and fifth-wheel trailers exhibit strong aerodynamic coupling effects with their towing vehicles—meaning the aerodynamic performance of the combination is not simply the sum of its parts. The wake from the tow vehicle directly interacts with the trailer’s leading edge, generating complex vortex shedding, recirculating flow, and pressure recovery zones. These interactions can alter not only drag but also lift, pitching moment, and lateral stability, making aerodynamic optimization a key enabler for safety, efficiency, and ride quality in RV systems.

At Caliber Technologies LLC, we use advanced Computational Fluid Dynamics (CFD) techniques to analyze and optimize the aerodynamic performance of travel trailers in combination with towing vehicles such as the Ford F-250. Our goal is to minimize the overall drag coefficient (CD), enhance towing stability, and ensure efficient airflow management between the truck and trailer system.

Objective and Methodology Overview

The primary objective of this project was to evaluate and reduce the total aerodynamic drag coefficient (CD) of a Ford F-250 towing a travel trailer, using a combination of CFD simulation, flow visualization, and shape optimization techniques.

Key goals included:

- Quantify baseline drag and pressure distribution across the vehicle-trailer combination.

- Identify high-drag regions caused by wake recirculation, flow separation, and turbulence.

- Propose and validate aerodynamic modifications to reduce CD without compromising packaging or usability.

- Improve towing stability by minimizing aerodynamic yawing and pitching moments.

The baseline CFD simulation revealed several critical flow phenomena contributing to the high drag coefficient:

- Separation at the trailer front wall due to the blunt frontal geometry and steep height transition from the truck cab to trailer face.

- Wake interference between the truck’s rear flow and the trailer’s leading edge, producing strong recirculation zones in the inter-vehicle gap.

- Vortex shedding along the trailer’s roof and side edges, contributing to pressure drag.

- Flow detachment behind the trailer’s rear face creating a large low-pressure wake region.

- The baseline aerodynamic drag coefficient (CD) for the truck-trailer system was found to be approximately 0.65, which is significantly higher than a standalone F-250 (CD ≈ 0.43).

| Parameter | Baseline | Optimized | Improvement |

| Total Drag Coefficient (CD) | 0.65 | 0.54 | ↓ 17% |

| Lift Coefficient (CL) | 0.06 | 0.04 | ↓ 33% |

| Yawing Moment (Mz) | 1.0 (normalized) | 0.83 | ↓ 17% |

| Pressure Recovery (rear face) | -220 Pa | -150 Pa | +32% |

Conclusion

The CFD-based aerodynamic optimization of a travel trailer towed by a Ford F-250 clearly demonstrates the effectiveness of simulation-led engineering. Using advanced flow simulation and shape optimization techniques, Caliber Technologies reduced drag coefficient by 17%, leading to tangible performance, efficiency, and comfort improvements. This study underscores the importance of integrating CFD early in the design cycle to guide geometric decisions and validate aerodynamic efficiency before physical prototyping—significantly reducing cost and development time.

At Caliber Technologies LLC, our CFD engineers specialize in external aerodynamics, underhood thermal management, cooling airflow, and aeroacoustics for the automotive, off-highway, and transportation industries.

Our capabilities include:

- Steady and transient CFD simulations using ANSYS Fluent, STAR-CCM+, and OpenFOAM.

- Design of Experiments (DOE) and optimization studies using parametric geometry tools.

- Coupled aerodynamic and structural (CFD–FEA) analysis for load prediction.

- Visualization of pressure and flow structures for design recommendations.

By combining CFD analysis, design optimization, and engineering experience, Caliber Technologies helps clients reduce drag, improve fuel efficiency, and enhance vehicle stability—from trucks and trailers to complete vehicle systems.