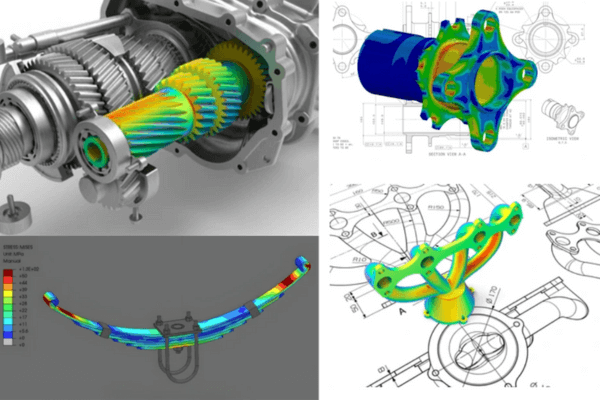

Saving money through engineering simulation involves several strategies to enhance design efficiency, reduce physical testing costs, and streamline processes. At Caliber Technologies, we deploy engineering simulations to represent various physics.

- Structural Analysis: Finite Element Analysis (FEA) is used to evaluate how products will react to physical forces, helping identify weak points and optimize structures for strength and durability.

- Fluid Dynamics: Computational Fluid Dynamics (CFD) simulates fluid flow around or through products, which is vital in industries like aerospace, automotive, and HVAC to improve efficiency and performance.

- Thermal Analysis: Thermal simulations assess how products will dissipate heat, helping design components that maintain optimal operating temperatures and avoid failure.

- Multiphysics Simulations: These combine multiple physical phenomena (like thermal, mechanical, and fluid interactions) to provide a more comprehensive understanding of product behavior under real-world conditions.

Engineering simulation plays a crucial role in product development by enabling teams to analyze and validate designs virtually before physical production. Here are some key approaches:

| Concept Validation | Early-stage simulations help validate design concepts by assessing feasibility and performance against requirements, allowing for quick iterations and refinements. |

| Design Optimization | Use simulation tools to optimize designs before creating prototypes. This can minimize material costs and reduce the need for multiple iterations. |

| Virtual Testing | Conduct virtual tests to evaluate performance under various conditions. This reduces the need for expensive physical tests and prototypes. |

| Failure Analysis | Utilize simulations to predict potential failures early in the design process. Identifying issues before production can save costs associated with rework and recalls |

| Material Selection | Simulate different materials and their properties to find cost-effective alternatives without compromising quality or performance. |

| Process Simulation | Model manufacturing processes to identify inefficiencies, reduce waste, and optimize production schedules, which can lead to significant savings. |

| Reduced Time-to-Market | By using simulations to refine designs quickly, companies can accelerate development timelines, bringing products to market faster. |

| Lifecycle Assessment | Perform simulations to evaluate the entire lifecycle of a product, identifying opportunities for cost savings in maintenance and end-of-life disposal. |

By incorporating these strategies, companies can leverage engineering simulation not only to enhance product quality but also to achieve significant cost savings throughout the development process. Overall, engineering simulation enhances decision-making, accelerates development cycles, and improves product quality, making it an essential tool in modern product development.